By virtue of being an FMCG company, we significantly rely on natural resources. They are inherent to our business for achieving long-term sustainable growth and hence we consider it our responsibility to judiciously manage the use of natural resources, and reduce the negative impact of our operations on the environment.

Achieving our environmental goals

In order to create the above impact, we have formulated a series of public commitments to be achieved and report their progress, year-on-year.

| Focus Area | Goal | Target year | FY20 result | FY19 result |

ENERGY

ENERGY

|

Reduce energy intensity (plant operations) GJ per unit crore revenue by 50% from FY13 base year | 2022 | 32% ^ | 25% |

EMISSIONS

EMISSIONS

|

Reduce GHG emission intensity (Scope 1 and 2) tCO2e per unit crore revenue by 75% from FY13 base year | 2022 | 68% ^ | 56% |

WATER

WATER

|

Offset 100% of water used in own operations through catchments and conservation measures | Continuous | Offset 3.2 times |

Offset 2.5 times |

PACKAGING

PACKAGING

|

Achieve ZERO PVC in packaging | 2022 | 0.14% | 0.4% |

| Increase recyclable packaging portfolio | 2025 | 95% | 94% | |

| Reduce packaging consumption MT per unit crore revenue by 10% from FY20 base year | 2025 | 6.54 | NA* |

^ The denominator for intensity reporting is changed from ‘per kg product manufactured’ to ‘per unit crore revenue’. The change is adopted due to shift in business operations in India during FY20. We initiated manufacturing in Sanand, Gujarat and discontinued at Kanjikode, Kerala. Further, there were also consolidation and expansion activities across our depots and third party manufacturing units (convertors) as part of our Planning & Logistics strategy. We anticipate more such shift in our business portfolio, going forward. Hence, to ensure comparability in our environmental performance disclosures year-on-year, we have shifted our intensity reporting denominator for all environment KPIs to ‘per unit crore revenue’.

* Goal is established this year. The progress will be reported from next reporting cycle onwards.

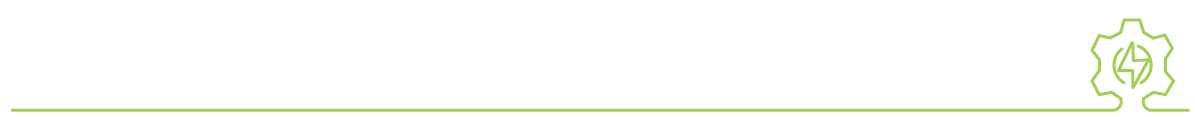

ENERGY

Our manufacturing operations fulfil energy requirements from a variety of sources like electricity from grid, furnace oil, diesel, wind power, solar power and biomass fuel. In the year 2020, total energy consumption stands at 340,152 GJ, out of which 267,624 GJ is contributed to direct energy consumption and 72,528 GJ contributed to indirect energy consumption. With respect to the 2022 energy intensity target, we have achieved 32% reduction against the 2013 base year and 6% reduction from the previous year. The initiatives undertaken during the year related to energy efficiency measures are highlighted in section 6.5 of the Business Responsibility Report (BRR).

Reduction in energy intensity from 2013

India operations: Energy intensity trend

The energy intensity reported is ‘per unit crore revenue’. However, we have retained the 2022 target to reduce energy intensity by 50% from base year.

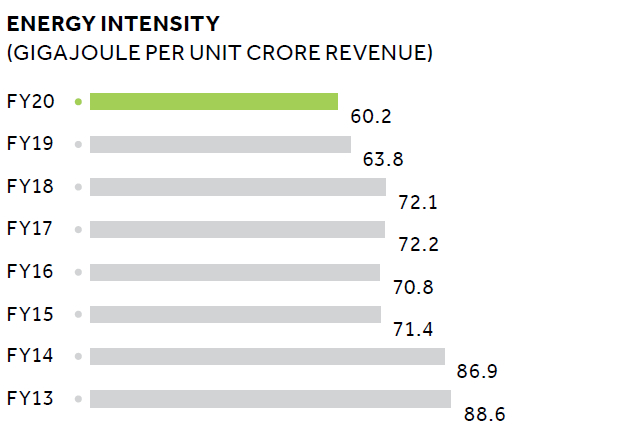

Overall renewable energy percentage

stands at 79% as on 2020, an increase

by 246% from that of base year and

9% from that of the previous year.

Renewable Energy

Our efforts to reduce dependency on fossil fuel and increase use of clean and renewable fuel continues to be in-line with our strategy. To this end, we have achieved significant reduction in the use of fossil fuels, which stands at 91% reduction from that of the 2013 base year. The thermal energy requirement at three of our manufacturing operations are derived from 100% renewable source (biomass).

Of total energy is from renewable source

India operations: Energy Mix FY20

ENERGY MIX (%)

CLIMATE CHANGE

Climate change is a pressing global issue and it requires urgent action. At Marico, we aim to play a catalysing role in order to actively address this challenge.

Our performance

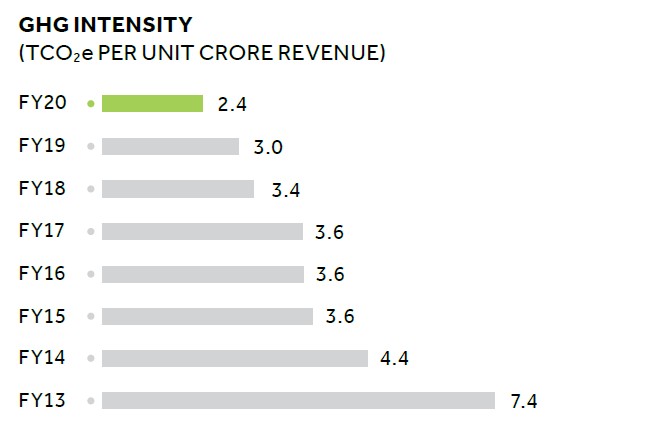

Marico remains committed in its journey on the low carbon pathway and have set a target to reduce GHG emission intensity (Scope 1 and 2) by 75% from the FY13 base year.

In FY20, the absolute GHG emissions (Scope 1 and 2) for India manufacturing operations stood at 13,520 tCO2e, which is 21% reduction from that of the previous year. Further, the GHG emission intensity (Scope 1 and 2) stood at 2.4 tCO2e per unit crore revenue, demonstrating reduction of 68% from that of the base year and 20% from the previous year.

Reduction in GHG emission intensity from 2013

India operations: GHG emission intensity trend

The GHG emission intensity reported is ‘per unit crore revenue’. However, we have retained the 2022 target to reduce GHG emissions intensity by 75% from the base year.

ACTION ON CLIMATE CHANGE

Carbon Neutral facility

‘Perundurai factory’ became Marico’s first manufacturing operation to be certified as a ‘carbon neutral’ facility during 2020.

Marico responded to the CDP 2019 Climate Change disclosure.

Scope 3 emissions

More than 95% of our GHG emissions can be attributed to our value chain. To account for this, we have completed inventory of Scope 3 emissions for all the categories applicable for Marico India operations in the value-chain.

In FY20, the Scope 3 GHG* emissions for India operations stood at 499,568 tCO2e, which is a 1.6% reduction from previous year.

India Operations: Scope 3 GHG emissions

| Scope 3 Categories | UoM | FY20 | FY19 | % change |

| Cat 1 - Purchased goods and services | tCO2e | 376,047 | 380,562 | -1.2 |

| Cat 3 - Fuel- and energy-related activities | tCO2e | 6,870 | 7,862 | -12.6 |

| Cat 4 - Upstream Transportation of Products | tCO2e | 45,257 | 42,512 | 6.5 |

| Cat 5 - Waste generated in operations | tCO2e | 12,138 | 14,184 | -14.4 |

| Cat 6 - Business travel | tCO2e | 1,668 | 1,639 | 1.8 |

| Cat 7 - Employee commuting | tCO2e | 1,208 | 1,124 | 7.5 |

| Cat 8 - Upstream Leased Assets | tCO2e | 24,751 | 27,013 | -8.4 |

| Cat 9 - Downstream transportation & Distribution | tCO2e | 3,748 | 3,665 | 2.3 |

| Cat 12 - End of Life treatment | tCO2e | 27,881 | 29,108 | -4.2 |

| Total | 499,568 | 507,667 | -1.6 |

To guide our efforts going forward, we have identified several key actions across our operations and value chain to minimise the climate change impact. The interventions include investment in renewable energy projects in our factories, replacement of fossil fuel with clean fuel in operations, business related travel optimisation, logistics optimisation, sustainable packaging solutions, recycling and reuse of waste, besides partnering with critical value-chain partners to implement green projects.

Emissions reduction through logistics optimisation

We have progressively improved our primary logistics

performance over the years. The fuel efficiency realisation

per tonne load of high capacity vehicles is better than that

of low capacity vehicles and in turn results in lower carbon

footprint. Keeping this in judgement, we have increased the

use of higher capacity vehicles from 1% in FY18 to 33% in

FY20, in our primary movements.

The initiatives have directly translated into reduction of diesel consumed by almost 4 litres per tonne of product transferred in our primary movements, translating to avoiding 2,975 tCO2e of GHG emissions.

* Calculated as per GHG Protocol Corporate Value Chain (Scope 3) Accounting and Reporting Standards

WATER

We use a host of agro-based raw material in our products, and hence water availability is crucial to ensure sustainable supply of input materials. Further, ensuring water security for larger community needs is an embedded belief in our corporate social responsibility philosophy.

* Watershed management projects completed in 2020 are reported in ‘Community’

Marico responded to CDP 2019 Water disclosure.

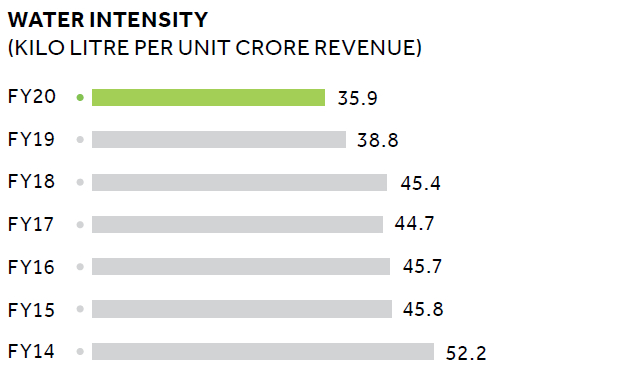

Reduction in water intensity from 2014

During 2020, we consumed 20.3 crore litres of water in our operations, a 9% reduction from previous year. The water intensity for India operations stood at 35.9 kilo litre per unit crore revenue, which is a decrease of 31% from year 2014, and 8% from the previous year. In our operations, we continuously evaluate and execute innovative projects to reduce fresh water consumption. During the year, we completed several projects to improve water efficiency and usage, including the construction of a rainwater harvesting pond, recycling of domestic sewage, eco water fittings, among others.

India operations: Water intensity trend

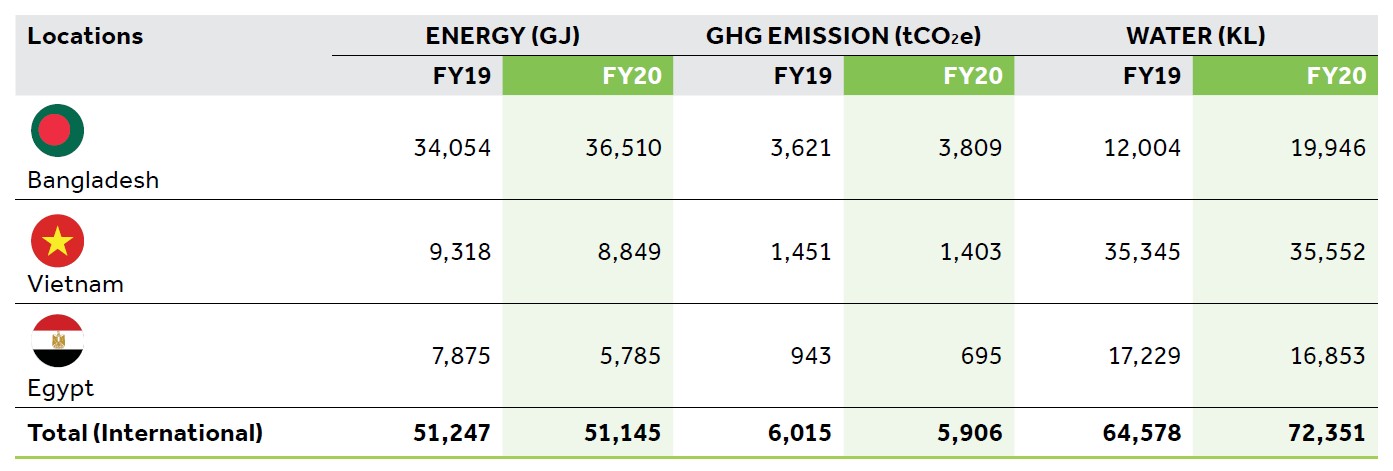

ENVIRONMENTAL PERFORMANCE:

MARICO INTERNATIONAL OPERATIONS

In 2020, we expanded our sustainability disclosure focus to Marico International locations. We have initiated reporting environmental performances covering energy, GHG emission and water for our international operations at Bangladesh, Vietnam and Egypt.

The total energy, emissions and water consumed by Marico India and International operations put together in FY20 stands at 391,297 GJ, 19,427 tCO2e and 27.5 crore litres respectively.

SUSTAINABLE PACKAGING

Packaging at Marico is critically appraised through the lens of design, material, manufacturability and consumer preferences, keeping sustainability at the core.

Of packaging material used in 2019-20

Of packaging material saved in 2019-20 through design and innovation

Of packaging material consumption per unit crore revenue for 2019-20

Of packaging material recyclable by weight as on 2019-20

Of post-consumer non-recyclable plastic waste collected and energy recovered in 2019-20*

*Executed as part of the Extended Producers Responsibility (EPR) requirement under Plastic Waste Management Rules.

Our packaging designs give signature identity to our brands. While we take pride in our distinguished identity through packaging we are also cognisant of the environmental and social consequences of using packaging materials. We constantly look for opportunities to improve and promote sustainability in our packaging portfolio. To enable this, we launched the ‘UpCycle’ programme, an initiative that echoes the philosophy of circular economy. Our endeavour under the programme is to establish and enhance value of packaging material at every stage of its life, with primary focus on plastic.

Weight optimisation

Marico has long been working on packaging weight reduction measures. During the year, the projects under design change and innovative efforts, coupled with modern techniques have led us to save 8,41,000 kg of packaging material. The interventions are exerted under the value enhancement approach by Marico. In several products, we have saved up to 60% and 30% of paperboard and plastic respectively, without affecting consumer delight, while providing parity performance characteristics.

Enhance recyclability and recycled plastic use

We have made steady progress on use of 100% recyclable packaging material. As on 2020, about 95% of packaging used by Marico is recyclable by weight. Continuing our endeavour to use recycled plastic, we spend considerable time and effort in finding greener opportunities. To highlight a few achievements till date – 20% r-HDPE used in household care brand and 50% r-LDPE used in shrink films for secondary packaging of edible oil brand. Further, trials are underway for several prototypes. We are in the process of extending the r-PET used in hair oil bottles. Successful trials have been done with 20% r-PET and we are on our way to implementation.

Eliminating PVC usage

We are committed to eliminating the use of PVC in our packaging by FY22, and are working towards an advance achievement of the target. At present, the use of PVC is 0.14% of the total packaging material used.

Strategic partnerships

Marico became member of ‘Un-plastic Collective’, an initiative co-founded by CII, UN Environment and WWF to minimise the externalities of plastic on ecological and social health of the planet.

Aligned with the national agenda on plastic waste management, we partnered with several agencies, multilateral bodies and NGOs with an aim to build awareness amongst consumers about plastic waste handling and encourage them to take an active role. We have created impact through several community awareness, collection drives, beach clean-up activity and medical tests for waste aggregators during the year 2020.

Responding to emerging regulations

Marico in-line with the Plastic Waste Management (PWM) rules has undertaken the Extended Producer Responsibility (EPR) towards collection and safe disposal of post-consumer non-recyclable plastic waste. The activity was carried out across several states in India along with approved agency partners. During the year, we have completed collection and safe disposal of 7,73,000 kg of non-recyclable plastic waste.