While we are continuously working with all our partners across the value chain to drive excellence together, it is crucial for them to realise our objective of responsible growth, ethos and integrity of doing business as well as our efforts to boost the local economy.

collaborate to evolve Marico’s quality, responsible sourcing and operational excellence journey.

Suppliers/Vendors

Our value-chain partners form the backbone of our business. Trust, inclusive growth, quality excellence and social responsibility are the main anchors in our relationship with our partners.

Converters

Converters or third-party manufacturers are crucial in the value chain, transforming our products into packaged finished goods.

Depots and warehouses

The Depots and Warehouses play a critical role as they drive quality and efficiency within the downstream distribution chain.

Logistic partners

Our logistics team drives various initiatives at each node to ensure that our distribution network is constantly evolving across service, cost and sustainability.

Suppliers

The Supplier Relationship Management (SRM) strategy at Marico operates with the philosophy of creating synergistic business goals that inspire our partners to strive for excellence while advancing their growth stories.

The sourcing team at Marico constantly strives to develop new vendors to ensure supply assurance. We have suppliers across various regions, who consistently provide us with the required ingredients and packaging materials. The sourcing team explores and on-boards newer vendors from local as well as unexplored geographies.

Ishant Goyal

Manager, AP Refinery

The procurement and central quality assurance team at Marico jointly drives the Supplier Quality Excellence (SQE) programme, which aims at capacitating our value-chain partners to accelerate performance and deliver excellence.

Mahesh Periwal

Director, Tirumala Oilchem India Pvt. Ltd.

Based on, and in line with the recognised schemes of Global Food Safety Initiatives (GFSI), our SQE programme aims at enabling value-chain partners to ensure that supplied products are safe, legally compliant and conforms to agreed quality specifications.

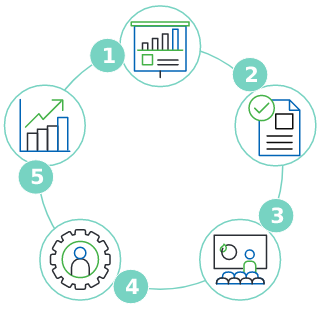

The scope of our SQE programme includes:

As part of Marico’s Responsible Sourcing Framework, SAMYUT , we encourage and take efforts to source locally produced and indigenous materials. We have 700+ suppliers, and 93% of the procurement by spend during 2021, was from local suppliers (for the India business). We believe that the focus on local procurement will help reduce the carbon footprint of our products and also boost socio-economic development.

Marico’s Responsible Sourcing Framework, SAMYUT, has been described in the Environment chapter of the Integrated Report.

Sustainable coconut conservation is a key part of India’s agricultural history, culture, and economic prosperity. There are around 20 Lakh coconut farms across the country, covering close to 45 Lakh acres giving ~16 Billion coconuts per annum. Marico buys a majority of the coconuts produced in the country through different channels.

In order promulgate the local economy by enabling smaller converters to sell to Marico, collections centres have been set up across key areas in Kerala, Tamil Nadu and parts of Karnataka. These collection centres function as connecting links between small farmers and Marico’s procurement team, ensuring quality, commercial viability, and access.

Significant efforts are undertaken to reduce the overall sustainability footprint of the coconut value chain based on principles of resource optimisation, circularity, ethical and responsible sourcing and socialeconomic empowerment to farmers.

The pandemic has transformed the economic canvas, pressurising businesses to rethink their growth stories in the next normal. In these unprecedented times, we are trying to stand with our partners and combat the pandemic-induced impacts together. In FY21, we addressed their immediate concerns. MSME vendors were paid in 30 days against the government mandate of 45 days to improve their working capital utilisation. We also extended payment terms to vendors wherever required. The rolling forecast was also shared with vendors to curtail disruptions due to unplanned business disruptions in the supply chain.

Converters

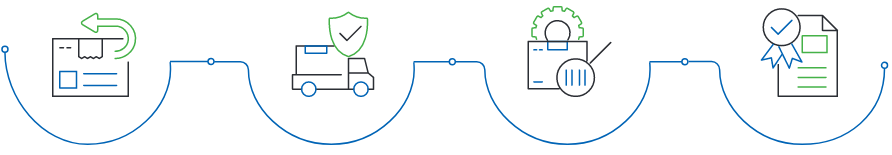

Converters or third-party manufacturers are crucial in the value chain, transforming our products into packaged finished goods. It is our vision to collaborate with our converters towards upgrading to best-in-class facilities so that we can continue to make products that consumers can trust. Towards this end, we work as a team with our converters on areas like technology, quality systems, process efficiency, operational excellence and safety, health, and environment (SHE) initiatives. Our endeavour is to establish synergistic and collaborative relationships that assure quality, foster innovation, and propel longterm sustenance.

As part of our continuous quality systems improvement journey, we are determined to accomplish acclaimed food safety certifications and recognitions for our converters to establish them as best-in-class facilities. We constantly work together and support our converters in areas like system and process changes, capability building of internal teams and modifying infrastructure requirements. These interventions demonstrate our focus on delivering the right quality and safe products to our consumers.

In FY21, our coconut cluster converters were certified with

COVID Safe Unit by SEA, HALAL by Halal India, FSSC 22000

version 5.1 by DNV. Additionally, external audits like NABL,

IEM and Deloitte Food Safety Assessment were completed

without any critical observations.

Depots and warehouses

Building capabilities of our business associates by consistently enabling performance excellence standards has always been a key area of focus at Marico.

Kaun Banega Champion (KBC) programme: A depot certification programme by Marico that aims to pursue and instill world-class standards and is now recognised as an industry benchmark. The KBC model focuses on Quality, SHE, Food Safety, Engagement, Supply Chain and Commercial Viability. Each of these have defined guidelines/ SOPs that are measurable, thus helping the depot personnel gauge their effectiveness. Periodic trainings are conducted at regular intervals to evaluate the performance improvements against these standards.

quality systems and processes in distribution chain

focus on depot safety systems

cost by efficient operations

with all regulatory requirements

Constant feedback from depot on product quality has led to improvement of Data Quality Review (DQR) i.e. Firsttime-right product. Overall, the current DQR level across depots stood at 99.7%

50% Reduction in Leakage and Damage (L&D)

100% Compliance with evolving regulatory landscape

LED lightings and installation of solar panels for energy efficiency and improved sustainability footprint across depots

Virtual engagement during the pandemic: Depot audits are carried out annually by our Corporate Audit team across India and these have raised the excellence bar, in terms of compliance to KBC modules. In FY21, due to the pandemic, the KBC audits could not be undertaken due to travel restrictions across India. However, to avoid any

business disruption caused by quality issues, the Marico’s Product Quality Assurance team conducted 15-18 virtual trainings across all key depots in India. These trainings focused on capacitating depot personnel to develop in-depth understanding on product storage requirements and criticalities related to quality defects.

Our manufacturing partners and depot operators need to follow a set of critical Safety, Health & Environment (SHE) qualification criteria to continue their associations with Marico. During the year, we engaged with 19 third party manufacturers and 25 depots during the year to help them establish the correct management systems for SHE. Monthly reviews were conducted for all warehouses to check preparedness as well as prevent any future incidents. At the end of the year, we engaged with an external auditing agency to ascertain the progress of each associate in their SHE journeys.

spent in FY21 to train depot staff and contractual workforce on various safety and quality norms as well as crisis management. Training themes - fire safety, electrical safety, loading/unloading techniques along with storage/handling, crisis management, Leakage and Damage, Food Safety, DQR & QMS Goods in Transit and waste management.

major incidents were reported in any of the depots and warehouses during the year, in continuation of the past five years’ trend

Apart from Quality Assurance, Operational Excellence and Occupational Health & Safety trainings, all value chain partners undergo mandatory certification on Marico’s Code of Conduct (CoC) and Marico Code of Business Ethics (MCoBE) at the onset of their business relationship

COVID-19 COMPLIANCE AND SUPPORT

Periodic assessments in the form of virtual audits were conducted to ensure 100% compliance with the evolving COVID -19 regulatory norms at all the depots and warehouses. The key objective of these audits was to train the depots on COVID -19 Protocol and assess any gaps or compliance requirements related to products, processes and facilities. A mediclaim policy was also issued for all depot staff members in case of anyone requiring hospitalisation support. Vaccination drives have commenced from May 21 for all warehouse related staff members.

AUTOMATION IN WAREHOUSES

We have implemented Warehouse Management System (WMS), a software application to monitor and control warehouse operations and materials. WMS has been implemented in three major warehouses – Sonipat in North, Coimbatore in South and Bhiwandi in West covering almost 25% of the overall space. WMS has helped us automate the basic functions of warehousing: goods receipt, storage, warehouse control, picking, retrieval and goods issue, and thereby improve productivity and stocks accuracy.

Logistics and transportation

Our aspiration is to create a supply chain system that is agile, cost competitive and sustainable, thereby leading to consumer delight. The logistics team drives various initiatives at each node to ensure that our distribution network is constantly evolving across service, cost and sustainability.

Process digitisation

For seamless indenting to payment process, digitisation of all logistics processes was carried out in a phased manner partnering with a startup, Pando. Our pain point was proof of delivery collection, which consumed significant time and resources of the partners. The implementation of the platform helped reduce vendor payment cycle times by 75%. The platform also helped in geofencing the facilities and thereby auto reporting of shipments through integrated SIM-based tracking. This implementation helped achieve compliance of 48% in shipment tracking for Q4FY21.

Mitigation of pandemic-induced disruption

Pandemic threw a wide range of challenges such as restricted movement/hauling of shipments due to announcement of lockdown, premium on freight and ability to bounce back to pre-COVID levels in terms of number of shipments. Our interventions were focused on direct billing from factories to our distributors and modern trade accounts, which resulted in retention of business. A bill to ship model was established in which depots supplied to stockists directly with steady flow of goods.

Both these interventions vastly improved supply chain distribution and we were able to achieve pre-COVID levels by May 20, when the countrywide e-way bill generation was at 45% of pre-COVID levels. This was required as a support during peak COVID times.