Environment

Environment

Environment

Environment

Minimising environmental footprint while delivering socially inclusive and responsible growth forms the core of Marico’s business DNA. As part of our ongoing 5-year sustainability roadmap (2017-2022), we have made every possible effort to stay true to our commitments and promises of leading our stakeholders towards a sustainable future.

Being an FMCG company, our business continuity is intrinsically connected with the availability of natural resources and a harmonious interplay of forces balancing the ecosystem. Our environmental goals, targets and endeavours not only attempt to safeguard the natural assets that facilitate our business sustenance but also futureproof the value that we deliver to the communities by minimising the impacts caused by our operations.

Conserve energy and reduce emissions

Managing sustainability footprint of products

Integrate circularity into packaging

Offsetting water consumption

Mitigate environmental risks in operations

Transform value chain sustainability

Conserve energy and reduce emissions

Emissions reduction

As a responsible business that aspires to actively contribute to the climate action agenda, we have undertaken bold steps and commitments to go beyond compliance boundaries and proactively reduce our overall emissions’ footprint across operations.

COMMITMENT

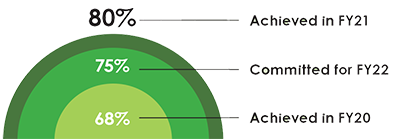

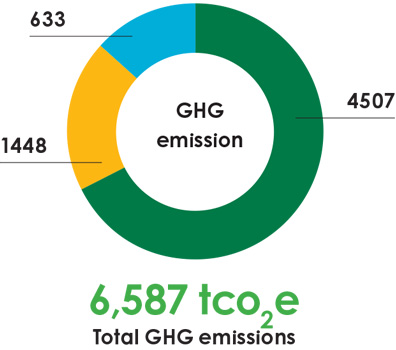

By 2022, reduce GHG emission intensity (Scope 1 and 2) tCO2e per unit crore revenue by 75% with FY13 as base year

FY21 PERFORMANCE

of GHG emission* in FY21 intensity stood at 1.5 tCO2e/unit crore revenue

PROGRESS

in GHG emissions intensity (Scope 1 and 2) as compared to base year FY13 and 38% reduction in intensity compared to FY20

Our 2022 targets of reducing GHG emission intensity by 75% has been achieved in FY21

A systematic GHG Emissions inventory (covering Scope 1, 2 and 3 emissions), risk-assessment and mitigation strategies, transition to renewables and a multitude of energy conservation initiatives have created a strong foundation for us to achieve our commitments towards our goals.

GHG EMISSIONS INTENSITY (tCO2e/unit crore revenue)

SCOPE 3 EMISSIONS

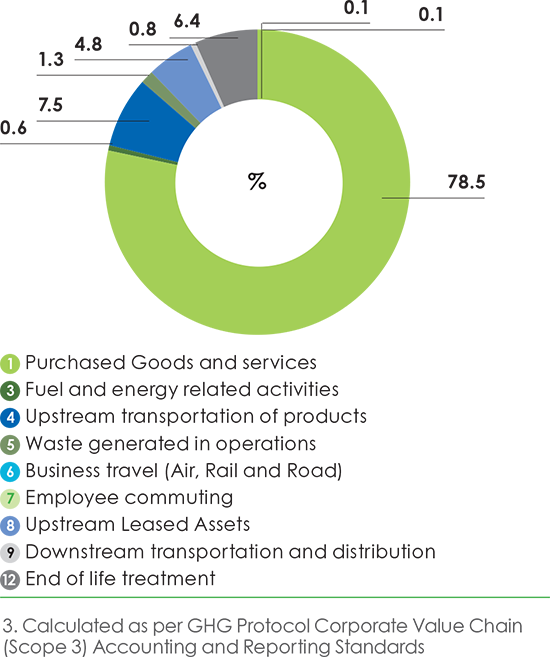

Our value chain3 accounts for 95% of the overall Scope 3 emissions. In order to have complete transparency and accountability towards our value chain emissions, we completed inventory of Scope 3 emissions for all the categories applicable for Marico India.

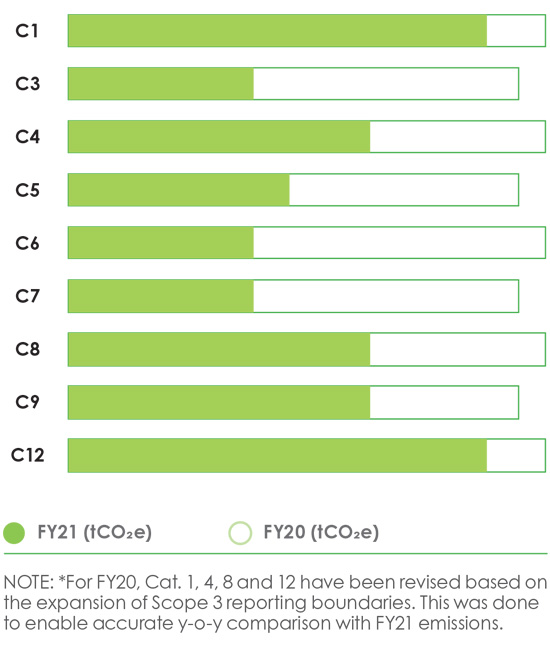

In FY21, the Scope 3 GHG emissions for India operations stood at 516,146 tCO2e resulting in a ~2% intensity reduction as compared to FY20. Change in manufacturing footprint landscape, operational shifts induced by the pandemic and enhancement of reporting boundaries as compared to the last two years resulted in the reduction.

Distribution of Scope 3 emissions by category

y-o-y comparison of Scope 3 emissions

FUTURE FOCUS AREAS

To guide our efforts going forward, we have identified several key actions across our operations and value chain to minimise the climate change impact. The interventions include:

Investment in renewable energy projects in our facilities

Replace fossil fuel with clean fuel in operations

Optimise business related travels and logistics

Sustainable packaging solutions

Recycling and reuse of waste

Partnering with critical value chain partners to implement green projects

On-job trainings and capacity enhancement towards quality, safety and

operational excellence

On-job trainings and capacity enhancement towards quality, safety and

operational excellence

At Marico, we have a constant focus on optimising our transportation networks to increase our supply efficiency thereby improving our overall emissions footprint. With multiple initiatives running throughout the year, we were able to achieve 13% reduction in emissions intensity of our logistics’ footprint (upstream + downstream) in FY21. Some of the key projects that made this possible are:

Interbatch Transfers (IBT) reduction: During FY21, a massive exercise targeted at reducing unplanned inter-depot transfers was undertaken. The use of modern techniques like demand sensing, coupled with efficient inventory optimisation and stock rebalancing methods, led to a reduction in inter-batch transfers by 59% across Marico supply chain network and also helped us in reducing our GHG emissions from road freight.

Distributed manufacturing footprints: FY21 witnessed an increased focus on distributed manufacturing from projects that involved optimising manufacturing footprints for some key products. Distributed manufacturing of Saffola oils with plants fully operational in East and South India, alternative facility for Oats manufacturing in the North, Value-added hair oils (VAHO) South unit producing South region centric stock keeping units of Parachute Aloe and Ayurvedic oil and commencement of production of Nihar Shanti Amla Badam (NSAB) in Sanand not only helped us optimise manufacturing but also contributed in reducing our overall carbon emissions from logistics and transportation activities.

Direct dispatch from factory: In FY21, we successfully adopted and implemented direct dispatch model of distribution. Our factories in the West and South were capacitated to dispatch huge volumes directly to our distributor partners. The direct billing from factory model aimed at eliminating resources utilised at depots and in transit leg of secondary freight from depot to distributors. This enabled us to reduce overall footprint and gave us a new medium to reach critical distributor partners efficiently even during a pandemic.

CARBON NEUTRALITY AND ECOSYSTEM RESTORATION

Marico’s Perundurai facility was certified as ‘Carbon Neutral’ by external assurance agency DNV GL. The plant completely operates on renewable energy sources and has been upgraded with smart energy installations that enhance its overall operational efficiency. Further, this plant has a Miyawaki forest comprising of 1100 trees within the premises. The forest provides a natural sink for carbon sequestration and restores the ecosystem.

The facility has been awarded the prestigious GreenCo Platinum rating certification. This facility also received ‘Platinum’ level certification for achieving the Green Building Standards by CII - Indian Green Building Council (IGBC).

CII’s Green Built Environment publication (Volume IV) recognises Marico’s Perundurai unit as a Champion redefining India’s Sustainability Landscape

CDP CLIMATE CHANGE DISCLOSURE

Marico responds to the CDP India Climate Change disclosure on an annual basis. In FY21, Marico was proud to receive A- rating, making its place among the top 16 Indian companies to receive the rating in 2020.

Climate Change

Energy conservation

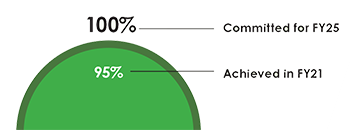

Our energy conservation initiatives focus on optimising energy consumption, installing energy efficient systems and technologies as well as transitioning to renewable sources. This is in line with the Decade of Action (2030) commitments towards transitioning to carbon neutral operations for all facilities and mitigating value chain climate impact in line with the 1.5 degrees scenario.

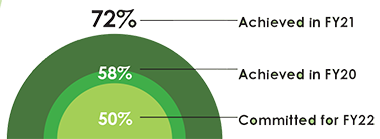

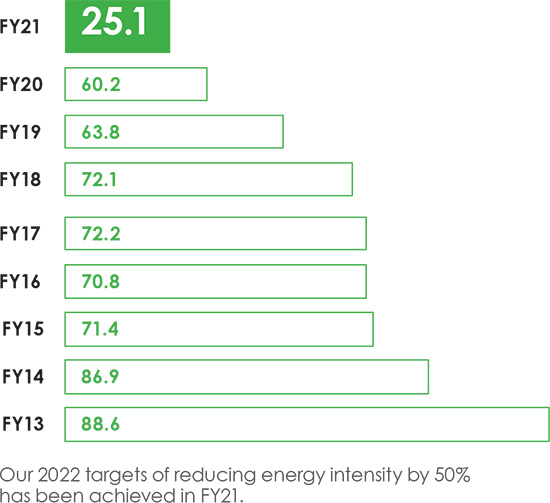

COMMITMENT

By 2022, reduce energy intensity (plant operations) by 50% as compared to base year FY13

FY21 PERFORMANCE

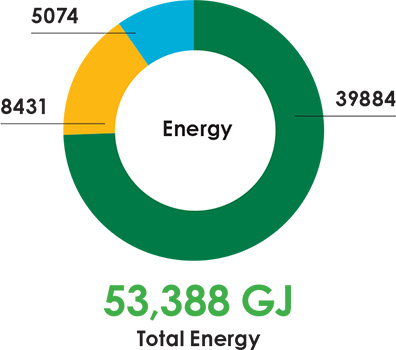

Total energy consumption of which 95,320 GJ is contributed by direct energy consumption and 60,274 GJ contributed by indirect energy consumption

PROGRESS

in intensity compared to base year 2013 and 58% reduction in intensity compared to FY20

ENERGY INTENSITY (gigajoule/unit cr. Revenue)

Tech-based interventions to improve energy efficiency

In FY21, a host of tech-enabled energy efficient measures were implemented across Marico’s facilities that led to total energy savings of 3,79,123 kWh/annum. Some of the key interventions deployed across facilities include improving operational efficiency of copra crushing process, installation of high-speed machinery that optimise consumption patterns, elimination of energy-intensive grinders and installation of automatic streetlight sensors, motion sensors for LED lights and photoconductivity principle-based Light Dependent Resistor (LDR) lighting units.

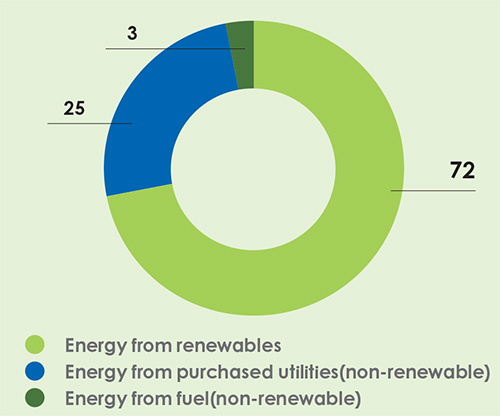

Low carbon energy transition

In FY21, three of our facilities – Jalgaon, Perundurai and Puducherry – transitioned to 100% renewable sources to meet their thermal energy requirements. Rooftop solar installations of 450 kWp at Jalgaon and 250kWp at Sanand facility were completed. At the Perundurai unit, 99% of the electricity was procured from renewable sources like wind, rooftop solar facility of 250 kWp and biomass. The expansion programme for the Perundurai facility has been centered around smart energy upgrades, including the installation of high-speed machinery to enhance overall productivity and operational efficiency. These alternate energy installations at factory locations have helped us reduce carbon emissions from energy consumption in FY21 by 4,957 tonnes CO2e.

FY21 - Energy Mix across India operations

Offsetting water consumption

We are promoting effective conservation, optimised resource usage and continual capacity creation towards a water secure future.

We are constantly exploring and implementing state-of-the-art solutions to minimise the dependency on fresh water sources and maximise internal operational efficiencies by recycling in house water consumed. Our objective is to become a water steward by replenishing 100% of water consumed in operations to ensure that sufficient quantities are available for community usage and agricultural purposes.

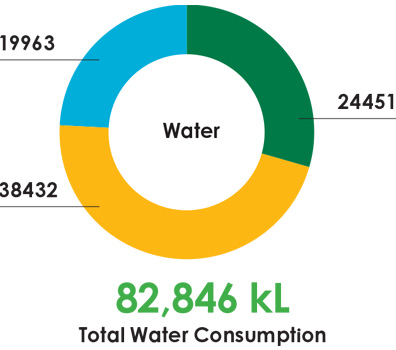

MEASURING OUR WATER FOOTPRINT

Jalaashay Initiative

This initiative focuses on capacity creation for community sustenance in water-stressed areas. This is done through a host of interventions including tank and pond rejuvenation, dam desiltation, construction of farm ponds etc. More than 100% water consumed in our operations is replenished through these interventions for domestic and agricultural usage.

Resource Efficiency and Process Optimisation across facilities

At Marico, our operational performance is pivoted on the principles of responsible production, circularity and resource optimisation. We have implemented measures to minimise operational water footprint, optimise processes and improve rainwater harvesting techniques, across all our units.

Zero discharge of treated water and effluents

Guided by the principles of Zero Liquid Discharge, all Marico operations have implemented systems and processes by which no industrial effluents leave the operational boundary of our facilities. 100% of the treated water is used within the fences for administrative and gardening purposes.

COMMITMENT

Green Water: 100% replenishment of water consumed in operations annually through rainwater harvesting methods (internal + external) for capacity creation.

Blue water: Optimise surface water usage in operations and promote

Grey Water: Zero discharge of domestic and industrial effluents beyond the fence*

FY21 PERFORMANCE

Total capacity creation in FY21

This includes:

Farm ponds in Tamil Nadu: 29.9 Crore litres and Damdesiltation activities in MP, UP and Rajasthan: 48.2 Crore litres**

10.9 Crore litres of water consumed across operations.

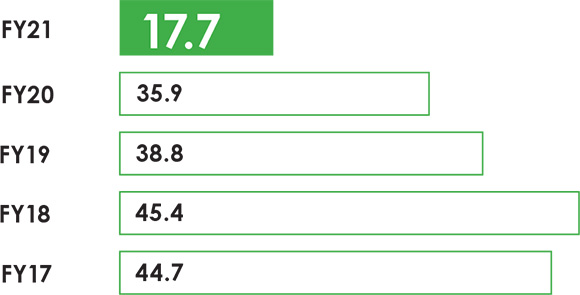

The water intensity for India operations stood at 17.7 kilo litre/unit crore revenue

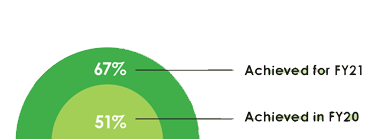

PROGRESS

of water capacity created till date

water consumption offset has been achieved for the past 4 years

intensity reduction as compared to base year FY14

intensity reduction compared to FY20

*The Grey Water related initiatives have been covered later under

the ‘Mitigate Operational Environmental Risks’ section

** The water stewardship projects are elaborated in the

Communities section of the report

WATER INTENSITY (kilo litre/ Crore revenue)

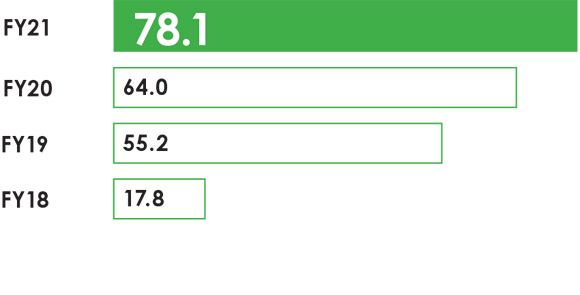

WATER STEWARDSHIP (Crore litres)

WATER NEUTRAL OPERATIONS

We have been harnessing the power of technology and scientifically advanced practices towards transitioning to water neutral operations. Marico’s Perundurai plant is a water neutral operation. By adopting a host of operational excellence measures such as water efficient systems, recycling processes and infrastructure towards substantial rainwater harvesting, this plant has been able to reduce water intensity by 68% in FY21 as compared to base year FY14.

CDP WATER DISCLOSURE

In line with our commitment towards securing shared water resources for business and community sustenance, Marico has been responding to the CDP India Water Security disclosure. In 2020, our CDP water security scores improved to B+. Our water stewardship program, Jalaashay was also recognised as an industry best practice towards addressing water security challenges in low rain-fed areas around workplace and factories.

OPTIMISING PROCESSES

A continual focus area is to optimise processes to reduce consumption intensity of water. We measure our consumption intensity using accurate metering facilities and maintenance of monthly logbooks at every facility. Based on our consumption patterns, we identify, formulate, and implement cost-efficient and innovative technologies that lead to an overall efficiency of using water as a resource.

Managing sustainability footprint of products

At Marico, integration of sustainability principles is considered with utmost significance at business and operational levels as well as at product levels. Our sustainable product strategy incorporates environmental and social considerations throughout the product life cycle by institutionalising innovation within organisation and stakeholders

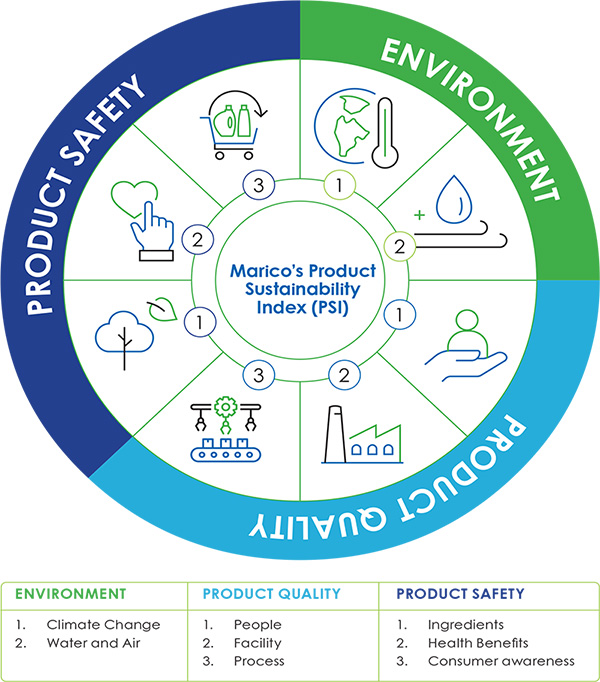

Marico’s Product Sustainability Index (PSI)

PSI is calculated considering three important aspects related to product – quality, safety and environmental footprint across lifecycle.

Using the various attributes of product quality, safety and environmental footprint (as shown in the model), we aspire to create a standard for defining ‘sustainable product’ and eventually move towards sustainable product portfolio.

COMMITMENT

Integrate sustainability considerations across products’ lifecycle (encompassing ingredient/material selection, sourcing, manufacturing, supply chain and end use)

Ensure 100% compliance on product quality, ingredient safety, transparent disclosure on product formulations

Accelerate consumer-centric product innovation to improve nutritional value of products*

FY21 PERFORMANCE

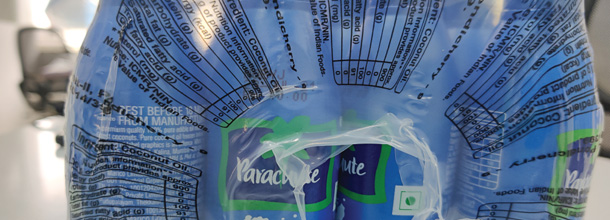

Product Sustainability Index (PSI) studies, based on Environmental LCA concept, have been undertaken so far for Marico’s key brands – Parachute Coconut Oil, Saffola Oil (Total and Gold) and Saffola Oats

PSI ASSESSMENTS

The PSI study for Parachute Coconut Oil, Saffola oil and Saffola Oats were aimed at quantification of environmental impacts across the life cycle (cradle to grave) aligned with Product Environmental Footprint (PEF) guidelines. The studies were undertaken in association with Sphera Solutions.

Estimation of environmental footprint using Life Cycle Approach

Mitigate environmental risks in operations

Environmental and social risk management framework is an integral part of Marico’s overall business resilience and continuity plans. We identify, measure, manage and mitigate these risks at strategic, organisational, operational and functional levels within our business ecosystem.

With respect to environmental and social risks emerging from our operational boundaries, the following fundamental aspects are considered:

Interventions to mitigate Operational, Environmental and Social Risks

AIR AND EMISSIONS

- Air quality monitoring

- Air emissions control

WATER

- Water intensity reduction

- Zero liquid discharge

WASTE

- Zero hazardous waste to landfill

- Self-waste consumption

COMMUNITY

- Community sustenance activities

- Social license to operate

Pursuing zero liquid discharge principles

A critical component of Marico’s efforts towards

safeguarding water resources is the adoption of smart

water recycling technologies and systems across

operations. Based on the principles of ‘Zero Liquid

Discharge’, our operations ensure that 100% of effluents

are treated within the plant boundaries thus preventing

any discharge to the external environment.

The principles of Reduce, Reuse, Recycle and Replenish are used to implement the commitments towards Zero Liquid Discharge. The treated water is used within the facilities for various administrative and gardening purposes.

A 4-R APPROACH FOR ZERO LIQUID DISCHARGE

Reduce

Through operational efficiency measures

Reuse

For various purposes within the plant boundaries

Recycle

To meet process requirements

Replenish

By construction of rainwater harvesting ponds

WASTE MANAGEMENT

As part of our overall endeavour to mitigate environmental risks, Marico is committed to minimise waste generation across its operations.

Sustainable Waste Management

As on FY21, most Marico facilities in India have adopted the ‘Zero Hazardous Waste to Landfill’ policy and is striving to implement the same by 2025. Currently, the entire quantum of waste generated during production and administrative functioning of the facilities is handed over to Central Pollution Control Board authorised vendors for recycling or scientifically appropriate disposal methods.

Self waste consumption

Driven by the principles of circularity, we are diligently pursuing the goals of making our operations waste neutral. This means that the waste generated within our operational boundaries (raw material handling and segregation, production, packaging etc) are either treated in-house for reuse or handed over to authorised recyclers for creating plastic pellets that can be added back into the material value chain. In line with our goal to make our operations 100% pellet loss free, we are working with our key partners towards ensuring that there is no leakage of micro-plastics or flakes.

Mapping environmental footprint of international operations

As part of Marico’s sustainability framework, we are committed to transforming the environmental performance of our international operations. This process was commenced in FY20 with the collection, analysis and reporting of environmental performance data on the three critical parameters – Energy, GHG Emissions and Water. Going forward, we will be measuring all KPIs that attribute to Marico’s group sustainability framework.

FY21 ENVIRONMENTAL FOOTPRINT ACROSS INTERNATIONAL OPERATIONS

Integrate circularity into packaging

At Marico, the packaging portfolio is pivoted on fundamental aspects like design, material, manufacturability, and consumer preferences, keeping sustainability at the core.

Upcycle, Marico’s flagship initiative, echoes the circularity principles towards minimisation of the environmental and social footprint of packaging at every stage of the value chain.

COMMITMENT

By 2025, transition to 100% recyclable packaging portfolio and introduce post-consumer recycled plastic in 30% non-edible product packaging

By 2022, phase out Polyvinyl chloride (PVC) usage in packaging

FY21 PERFORMANCE

of packaging material recyclable by weight as on FY21

of post-consumer plastic waste collected and disposed in environmentally safe manner.*

PVC content in packaging

* Executed as part of the Extended Producers Responsibility (EPR) requirement under PWM Rules.

Key pillars of the Upcycle initiative

EXTENDED PRODUCER RESPONSIBILITY

USE OF RECYCLED PLASTICS

ELIMINATE RISK

INNOVATION

Enhance recyclability and recycled plastic use

Continuing our endeavour to use recycled plastic and improve the recyclability quotient of our packaging portfolio, we undertook a wide range of initiatives that enhance circularity. Some of the key ones include:

RECYCLED PET IN HAIR OIL BOTTLES

In our effort towards increasing the quantum of recycled materials in product primary packaging, we successfully ran a commercial trial of recycled PET (r-PET) for one of our value-added hair oil brands. To implement this pilot initiative, we tied up with a key strategic vendor and a converter partner, to provide us with a regular supply of r-PET bottles at our Sanand unit which primarily manufactures value-added hair oil brands. The success of this initiative has propelled us to strategise future interventions for other brands in this category.

Jitendra Mahajan,

Chief Operating Officer

Supply Chain, IT & MENA Business, Marico Limited

POST-CONSUMER RECYCLED FILMS

In FY21, we formed a tripartite strategic partnership with Dow and Lucro Plastecycle, a homegrown Indian recycling company, to collect plastic waste in the form of films from the market, scientifically segregate and then reprocess into recycled polymers. These recycled polymers were later converted to more than 23,000 kg of plastics material in only three months, achieving an emission reduction of 486 tCO2e.

Reducing use of packaging material

As a part of our efforts to reduce consumption of packaging materials, we leveraged the power of design innovation based on various concepts of dematerialisation. During the year, the projects under design change and innovative efforts coupled with modern techniques saved substantial quantity of packaging material. Some of the key interventions undertaken in FY21 include optimisation of carton dimensions, removal of partitions and leaflets and jar weight reductions. Our Parachute Coconut Oil HDPE bottle and Hair Oil PET bottle are industry benchmark for being the lowest in weight (bottle and cap included).

Extended producer responsibility

Marico, in-line with the Plastic Waste Management (PWM) rules 2018, and the subsequent amendments, has undertaken the Extended Producer Responsibility (EPR) towards collection and environmentally safe disposal of post-consumer plastic waste. The activity was carried out across several states in India along with approved agency partners. During FY21, we completed collection and environmentally safe disposal of 16,30,000 kg of plastic waste as compared to 7,55,000 kg in FY20.

Abhishek Deshpande

Cofounder, Recykal

(A Producer Responsibility Organisation supporting

Marico’s EPR commitments)

Transform value chain sustainability

Integrating sustainability principles within the entire value chain is a critical area of focus in Marico’s Sustainability Framework.

We believe that promotion and adoption of responsible practices throughout the value chain can stimulate demand for socially and environmentally preferable products.

Marico’s Responsible Sourcing Framework’ titled ‘SAMYUT’ was institutionalised in 2018, in alignment with the overall business purpose of creating shared value. We believe that extending sustainability to our business associates will help foster innovation and meet evolving consumer preferences, besides realising our goal of delivering inclusive growth.

The intent of Marico’s Responsible Sourcing Policy is “Source material and services for Marico products through sustainable and responsible suppliers or business associates who share our sustainability vision”.

THE OPPORTUNITY

PRODUCT DEVELOPMENT

LEAN AND GREEN MANUFACTURE

SUSTAINABLE PROCUREMENT

SUPPLY CHAIN

SAFE DISPOSAL

KEY THRUST AREAS UNDER MARICO’S RESPONSIBLE SOURCING FRAMEWORK

ETHICAL STANDARDS

A business without ethics cannot win the trust of its stakeholders. Our philosophy is to conduct our business with high ethical standards in our dealings with all stakeholders.

ENVIRONMENTAL PROTECTION

A sustainability-focused organisation ensures that its processes are Green. We expect our suppliers and business associates to follow this and comply with all environment regulations.

SOCIAL COMMITMENTS

Local communities and society provide the social license to conduct our business. Hence, we believe it is vital to demonstrate social responsibility by promoting values.

COMMITMENT

By 2022, certify 20% critical value-chain partners on Level 1 (Educate)

By 2030, certify 100% critical partners on Level 1 (Educate) and 50% on Level 2 (Evaluate)

A maturity-based three phased engagement approach is adopted towards implementation of the framework:

1. EDUCATE

Communicate and create awareness amongst suppliers on the SAMYUT requirement. The suppliers are expected to give their consent to and sell declare their compliance and/or non-compliance to the level 1 questionnaire

2. EVALUATE

Marico intends to evaluate the performance of suppliers original set KPIs and goals. The suppliers are expected to retain attested documentation for review and adult as per the level 2 questionnaire

3. EVOLVE

Marico, in consensus with the supplier, will undertake joint projects and share technical know-how to improve processes and practices. The aim is to build a robust, strong and sustainable nexus towards a common objective

FY21 PERFORMANCE

of Marico’s critical value chain partners have completed Level 1 (Educate) certification. This includes 88% critical raw-material and packaging material suppliers.

Types of Suppliers:

RAW MATERIAL

RAW MATERIAL

PACKAGING MATERIAL

PACKAGING MATERIAL

CONVERTERS

CONVERTERS

LOGISTICS

LOGISTICS

WAREHOUSING

WAREHOUSING

Level 2 certification framework (Evaluate) has been developed for rollout in 2021. It includes a robust external auditing mechanism to monitor the value-chain partners’ performance across the key thrust areas

Ishant Goyal

Manager AP Refinery