ENVIRONMENT

FUTUREPROOFING

assets for tomorrow

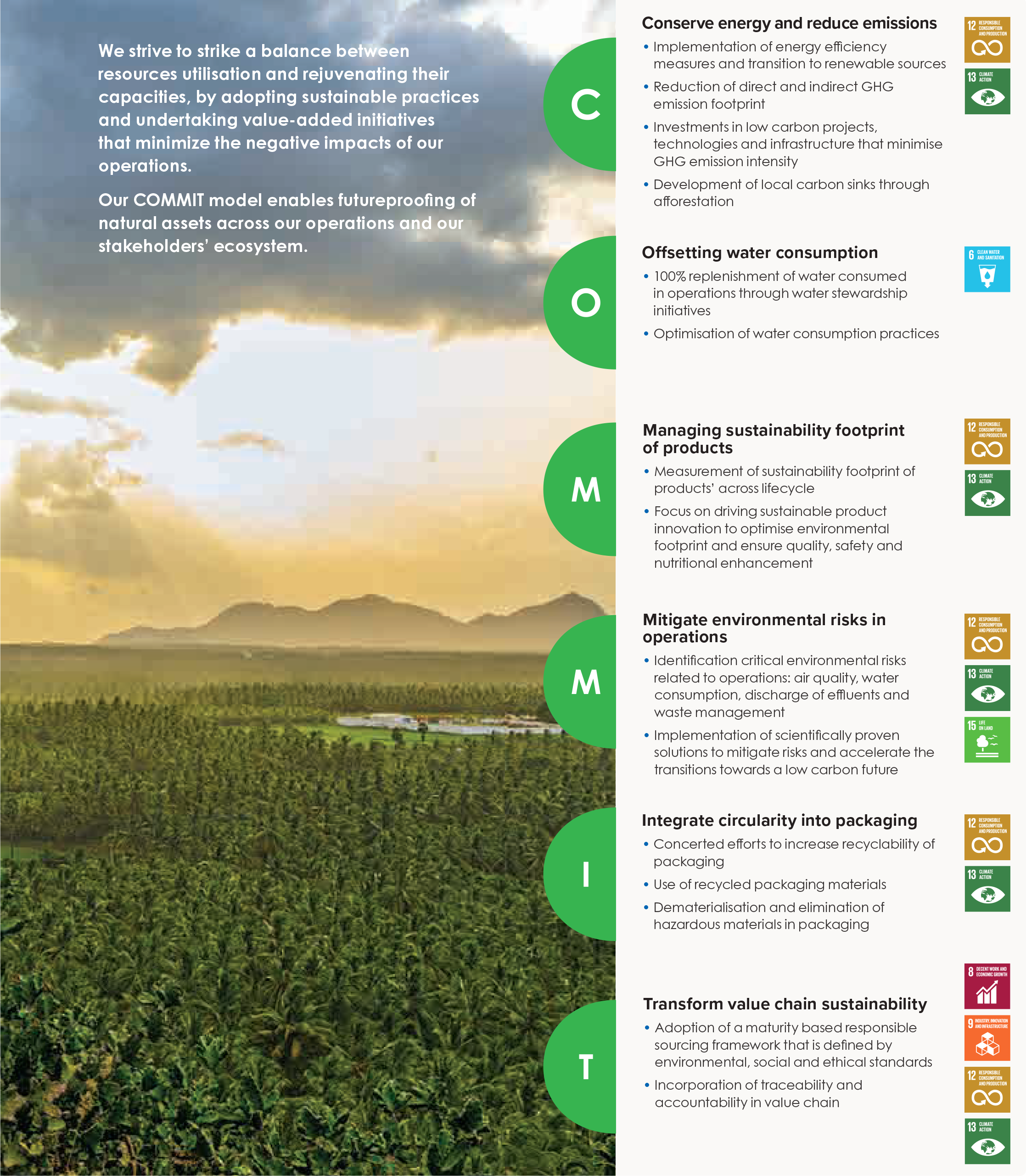

Environmental sustainability is a crucial element of Marico’s purpose-led long-term strategy. Owing to the nature of our products, we share an intricate relationship with natural resources and preserving them is our prime responsibility. Impact objectives of resource optimisation, responsible consumption, climate resilience, sustainable manufacturing operations and waste minimisation are deep rooted in our company goals. We intend to amplify our efforts such that we benchmark ourselves against the global best practices and expand our horizons towards protection of natural assets across our global business footprint and beyond.

"The Earth is all we have in common."

– Wendell Berry

Expanding horizons in the decade of action

Marico’s first 5-year sustainability roadmap was launched in 2017, with targets mapped till 2022. Since FY18, our sustainability impact goals have driven responsible growth and boosted capabilities, helping our business processes, systems, and operations, to address material issues related to environmental conservation and social empowerment. These impact areas and goals have capacitated the business to prioritise risks, create shared imperatives, and leverage on opportunities to drive a sustainable and socially inclusive future for all.

Having surpassed the first 5-year sustainability goals (2017-2022), we have moved on to identify all business-critical environmental aspects that are material to our business ecosystem, and set ambitious yet quantifiable targets for each of them as part of our decade of action roadmap (2022-2030).

2040 Net Zero Goal in Operations

Marico has taken up the target of achieving net-zero emissions across global operations by 2040

Achieving net zero in global operational emissions

As a responsible business that aspires to actively contribute to the climate action agenda, we have undertaken bold steps and commitments to go beyond compliance boundaries, proactively reducing our overall emissions’ footprint across operations. These commitments have been consolidated to form our net zero emission reduction targets in global operations by 2040.

Conserve Energy and Reduce Emissions

Conservation of energy and minimisation of organisational emissions footprint are comprehended by Marico as the first step towards establishing a climate-first business agenda.

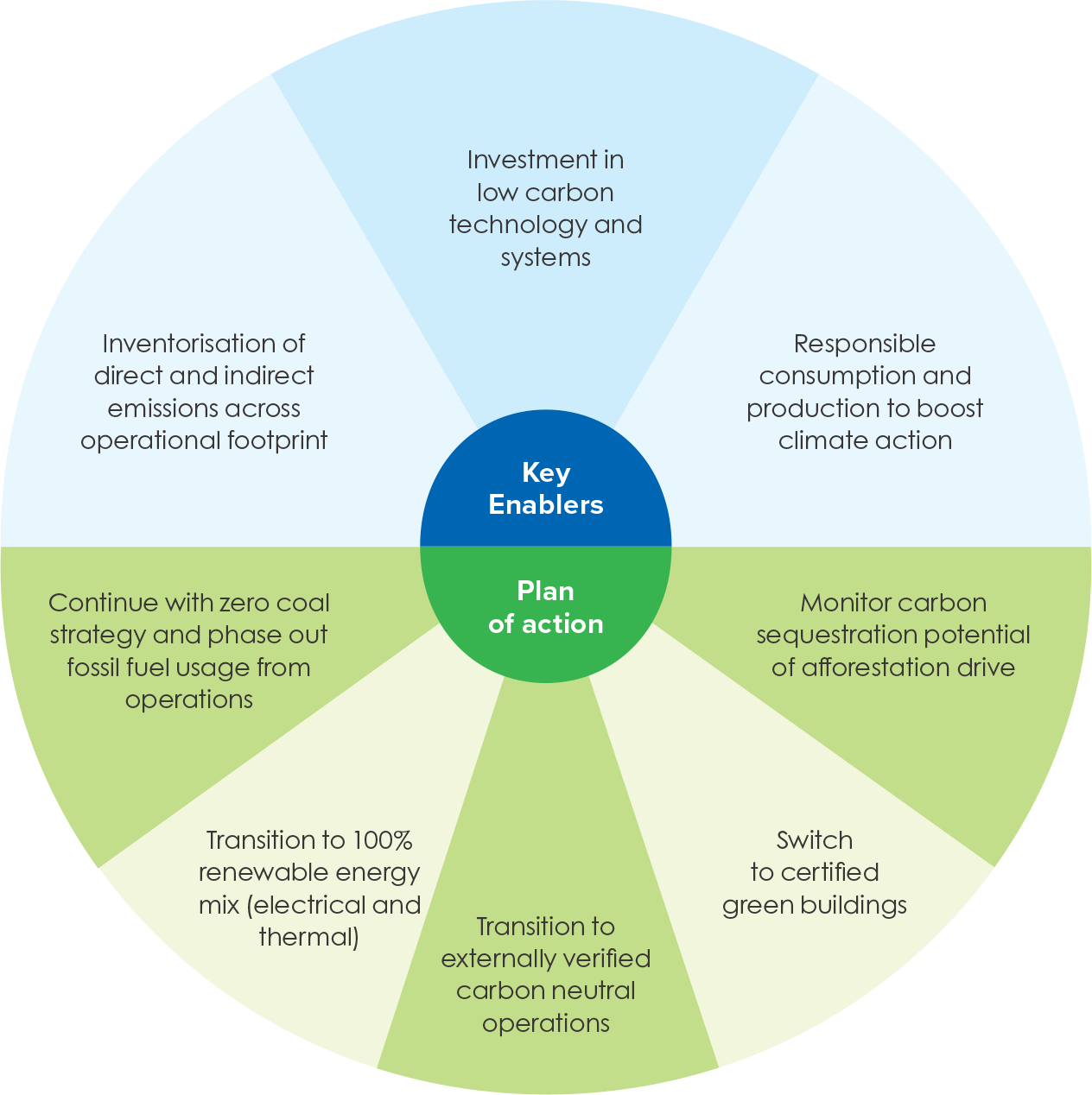

Being cognisant of the climate-related risks that arise from high energy demand, we have developed a robust carbon management strategy that prioritises actions related to energy efficiency, fossil fuel avoidance, renewable energy transition, carbon forestry, and reduction of carbon footprint across our product’s life cycle.

In FY22, we had set forth a course of action that would majorly contribute to our net zero target, beside preserving non-renewable resources, and protecting the Company against volatile energy markets.

Course of action towards net zero target

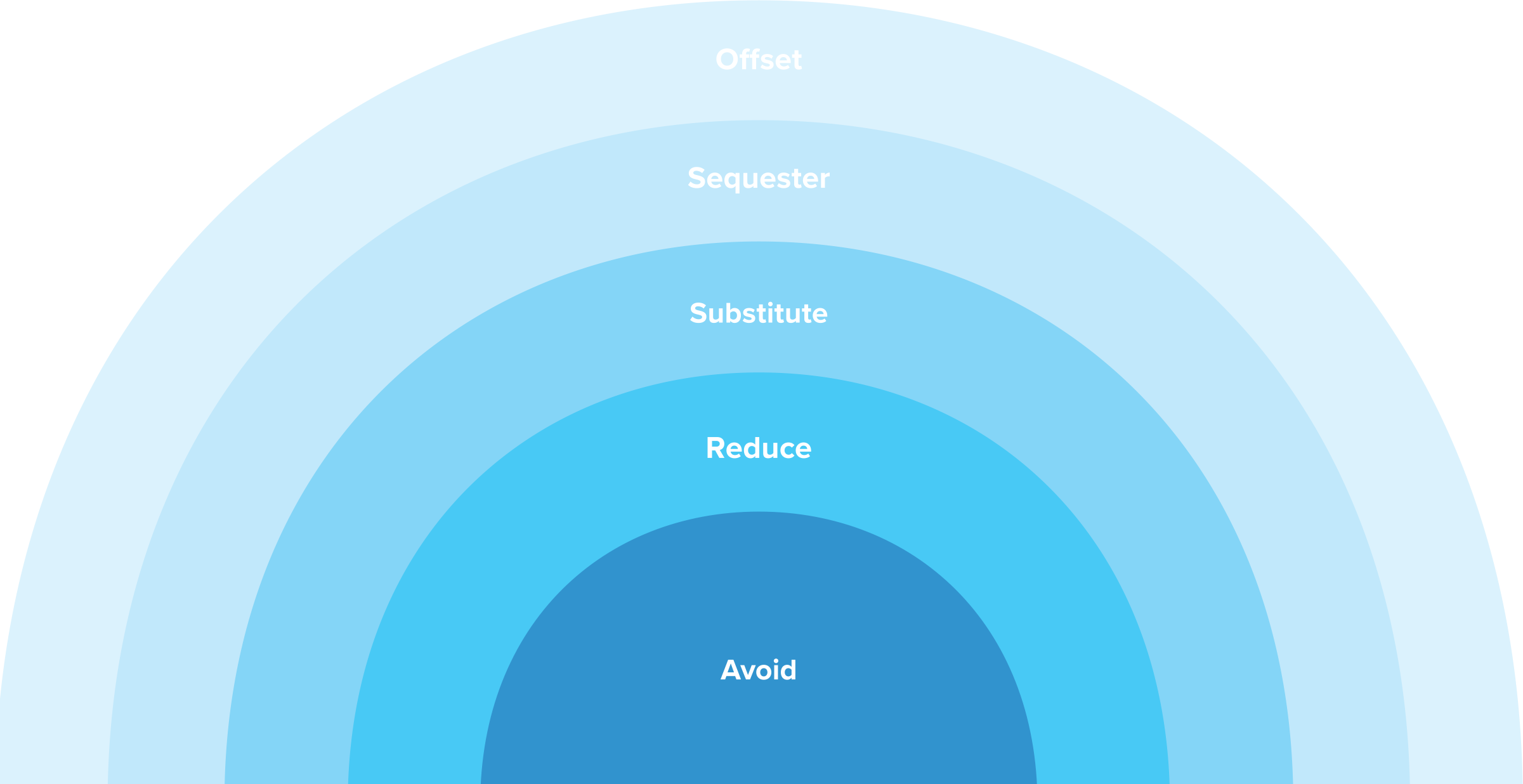

Avoid activities that cause emissions

Business model change, process change

Change activities to reduce to reduce emissions

Changes in layout, equipment elimination

Change sources to reduce emissions

Design change, equipment modification

Undertake activities to store emissions

Carbon forestry

Offset residual emissions

Carbon credit purchase

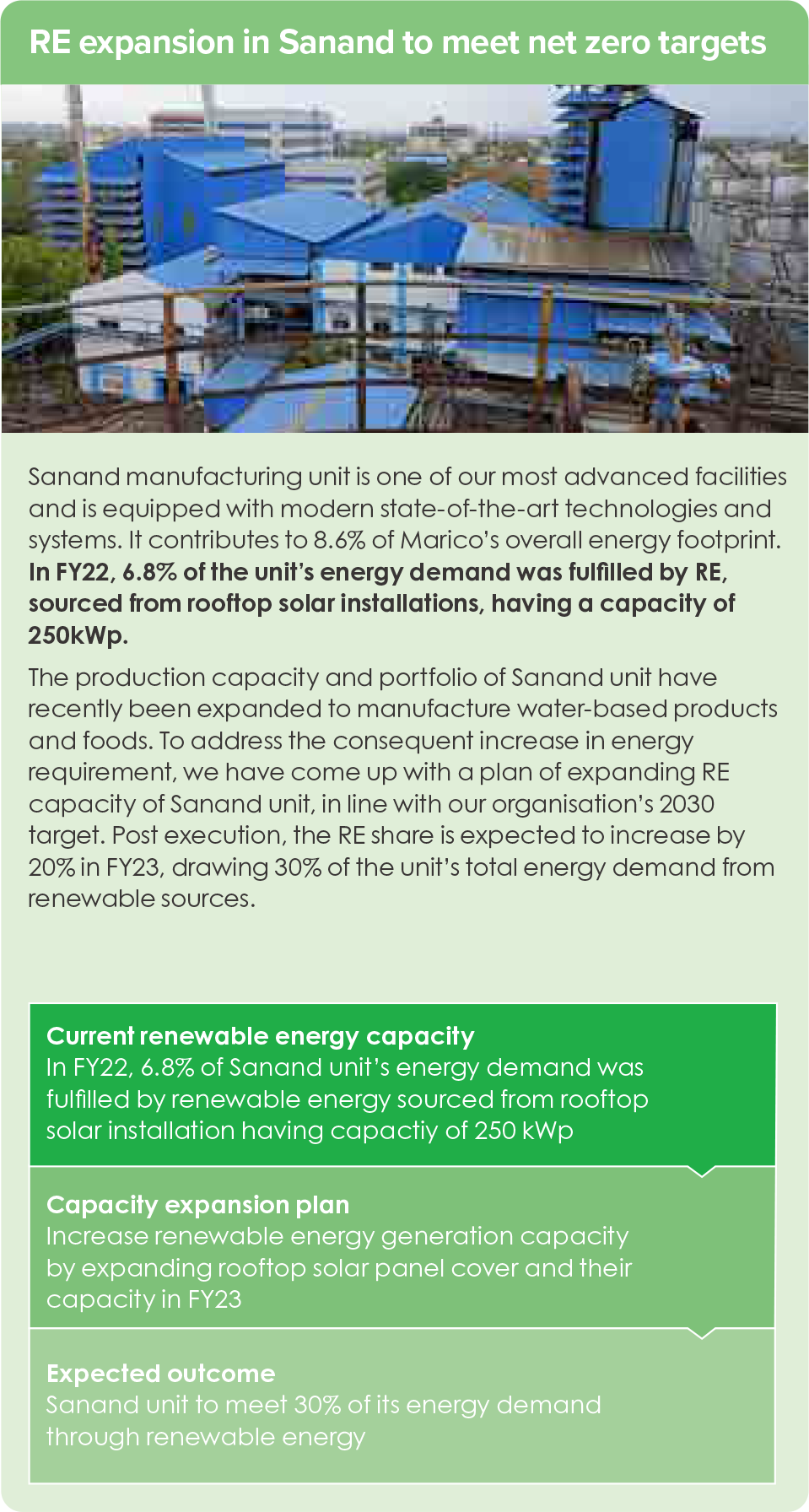

Net Zero Emissions Target for India Operations

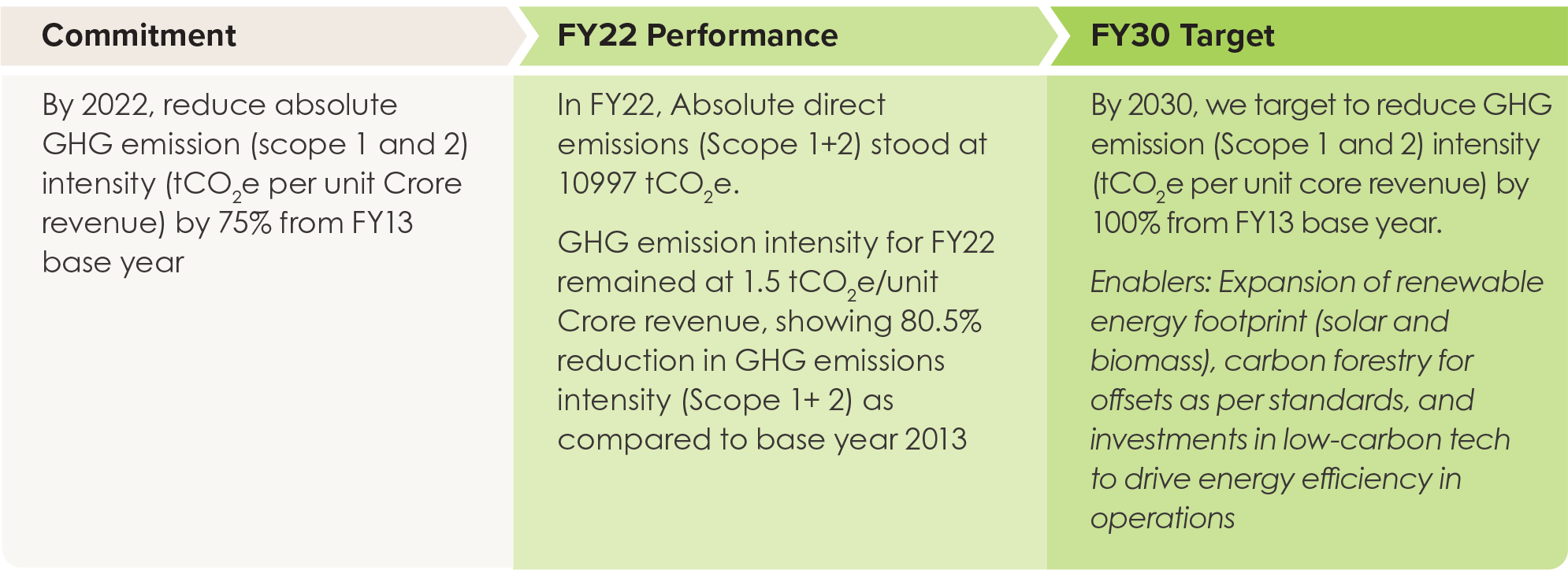

Marico Limited (India Business) commits to reduce Scope 1 and Scope 2 GHG emissions by 93%, and offset remaining 7% emissions through sequestration, and carbon offset by 2030, from the baseline year FY13.

To drive Marico’s net zero agenda, we have categorised our manufacturing profile, based on its climate-action potential to ensure cross-functional capacity enhancement and successful completion of targets with no major business barriers caused in the process.

A systematic GHG inventory is maintained to identify and quantify all direct and indirect (Scope 1, 2 and 3) emissions from our operations and value chain. We aim at gradually imbibing each of our units into the transitional pathway of carbon neutrality by optimising their energy footprint, investing in low-carbon technology to minimise operational emissions, switching to renewable sources of energy to meet operational requirements, and opt for local carbon sinks to sequester carbon for offsets.

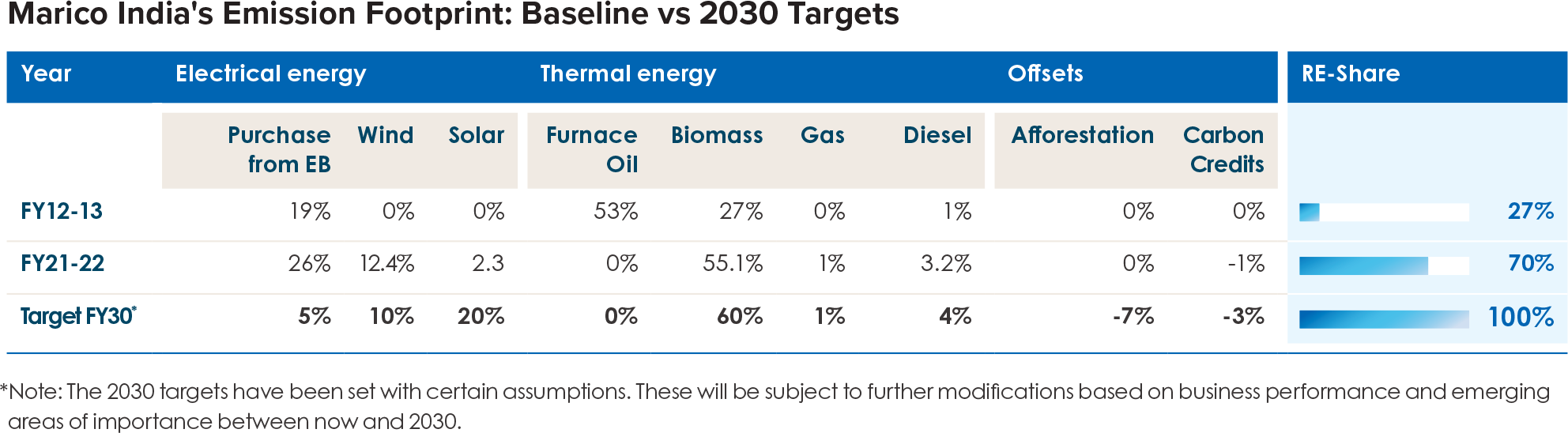

Marico India's Emission Footprint: Baseline vs 2030 Targets

We believe that the aforementioned targets will enable us to contribute significantly towards India’s commitments for United Nations’ Sustainable Development Goals (SDGs), in particular Goal 7, to ensure universal access to affordable, reliable and modern energy services, and take significant strides towards increasing the share of renewable energy in the energy mix, and the improvement of the energy efficiency rate.

Absolute Emissions (Scope 1+2)

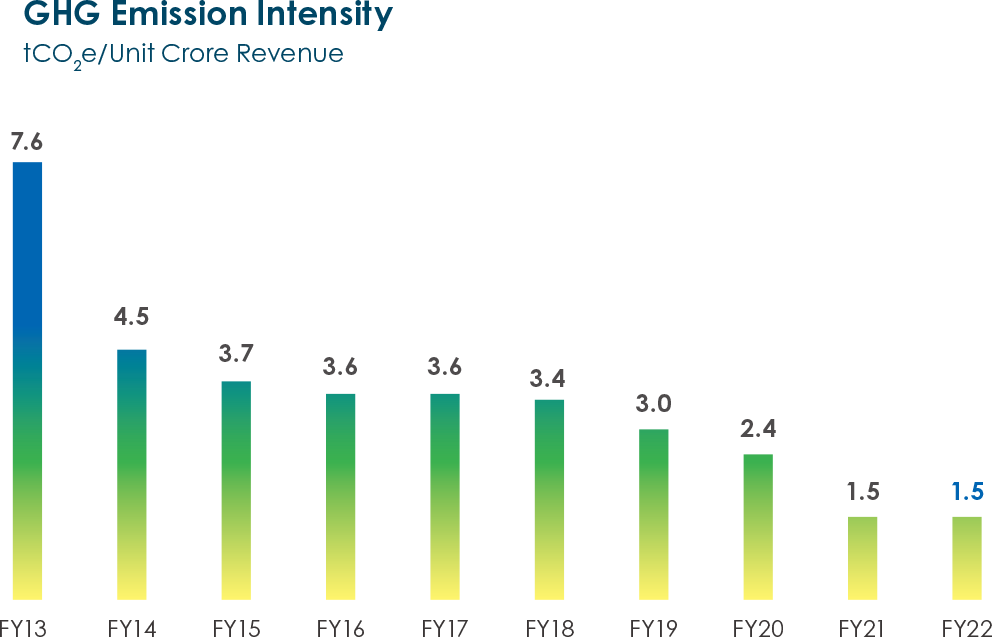

Our emission accounting was initiated a decade ago, earmarking FY13 as the base year for our first 5-year roadmap that ended in FY22.

Steady decrease in y-o-y GHG emission intensity is attributed to our constant efforts to improve operational efficiencies, adoption of energy saving mechanisms, use of clean fuel like bio-briquettes, and inclusion of renewable energy in our portfolio.

These efforts have also helped us to over-achieve the set emission reduction target, despite a growing manufacturing footprint.

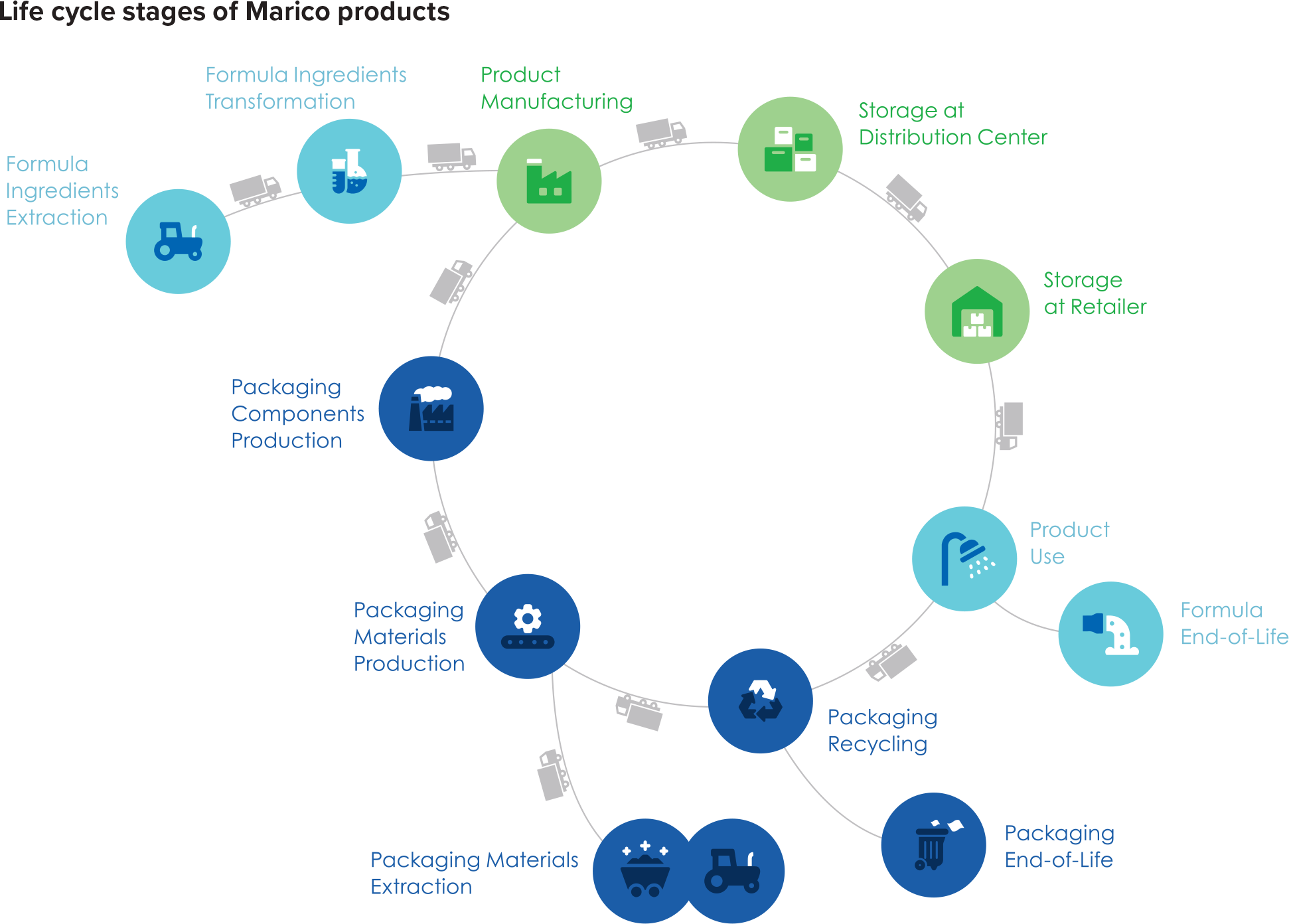

Scope 3 Emissions Footprint)

Indirect emissions (Scope 3) occurring in Company’s value chain, both upstream and downstream, often account for majority of its GHG footprint. It has been observed that more than 95% of our overall GHG emission is contributed by Scope 3. Monitoring and accounting this emissions trajectory, helps firm up our strategies to identify reduction opportunities, and frame carbon minimisation solutions across our value chain.

To maintain transparency, and better align with our goals to become a carbon-neutral business, we calculate Scope 3 emission footprint of the entire organisation by compiling relevant categorywise emissions data. The reporting boundary of each Scope 3 category is limited to ‘operational influence’ and is aligned with on the Science-based Targets initiative. Emission factors for each material or fuel are referred from the Greenhouse Gas Protocol.

In FY22, the Scope 3 GHG emissions for India operations stood at 5,61,192 tCO2e, resulting in ~12% reduction in Scope 3 Emission Intensity as compared to base year FY19. The post pandemic boom lifted some of the critical business hauls, induced in glocal market dynamics, thus causing an increase in the absolute indirect emissions footprint for the year for most companies. This has led to a significant reduction in our overall Scope 3 emissions intensity as compared to base year FY19.

In FY22, the Scope 3 GHG emissions for India operations stood at 5,61,192 tCO2e, resulting in ~12% reduction in Scope 3 Emission Intensity as compared to base year FY19.

However, as a future-forward company, we have identified the critical business risks associated with increase in Scope 3 emissions across each of the relevant categories.

Quantifiable and pragmatic reduction targets have been taken over a short, medium and long-term by integrating them in cross-functional KPIs, and performance incentive scorecards. Optimisation of business-related travels, reconfiguration of logistics footprint, sustainable packaging solutions, recycling and reuse of waste, and joining forces with critical value chain partners to implement green projects, top the charts.

Certified Carbon Neutral Operations

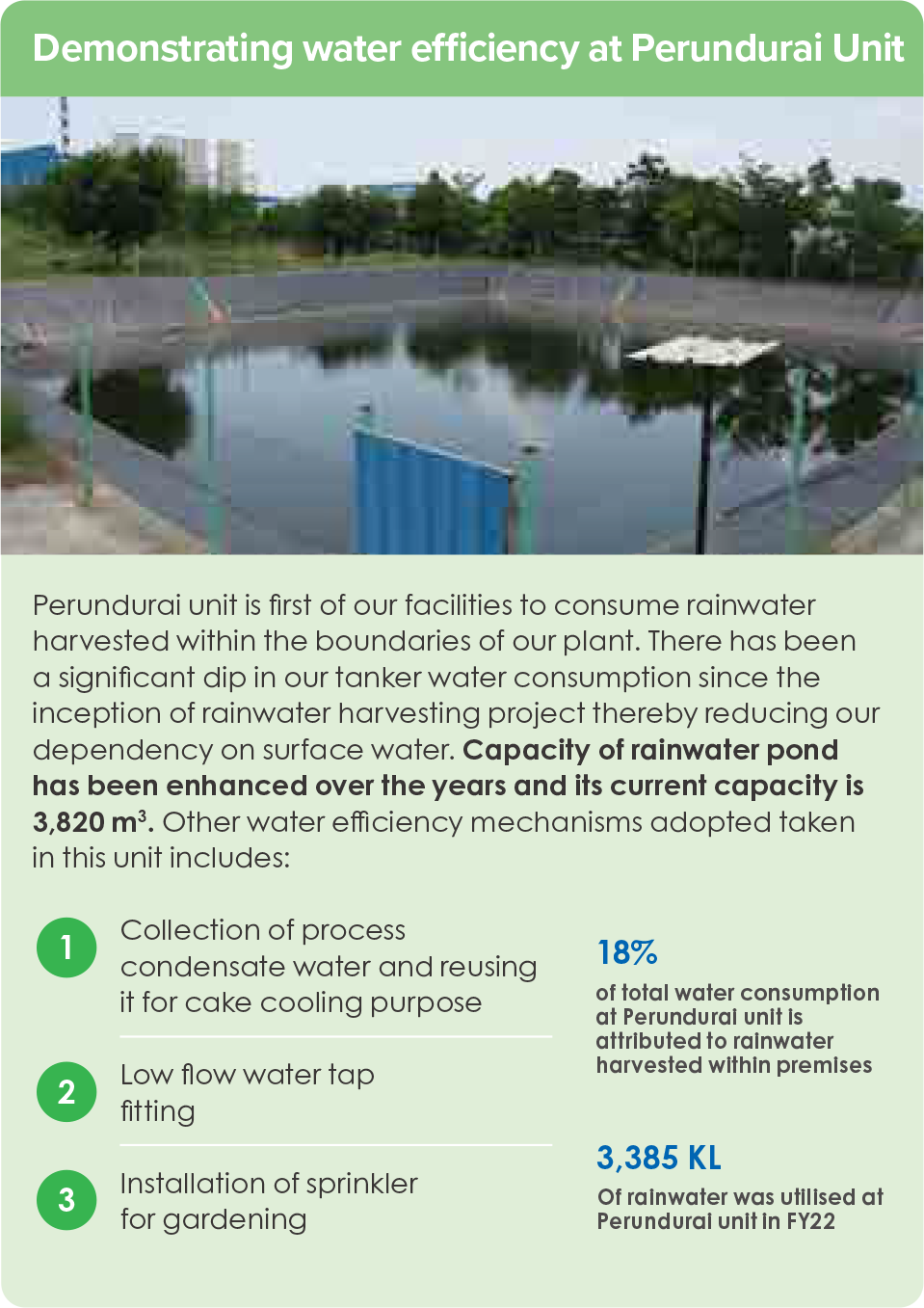

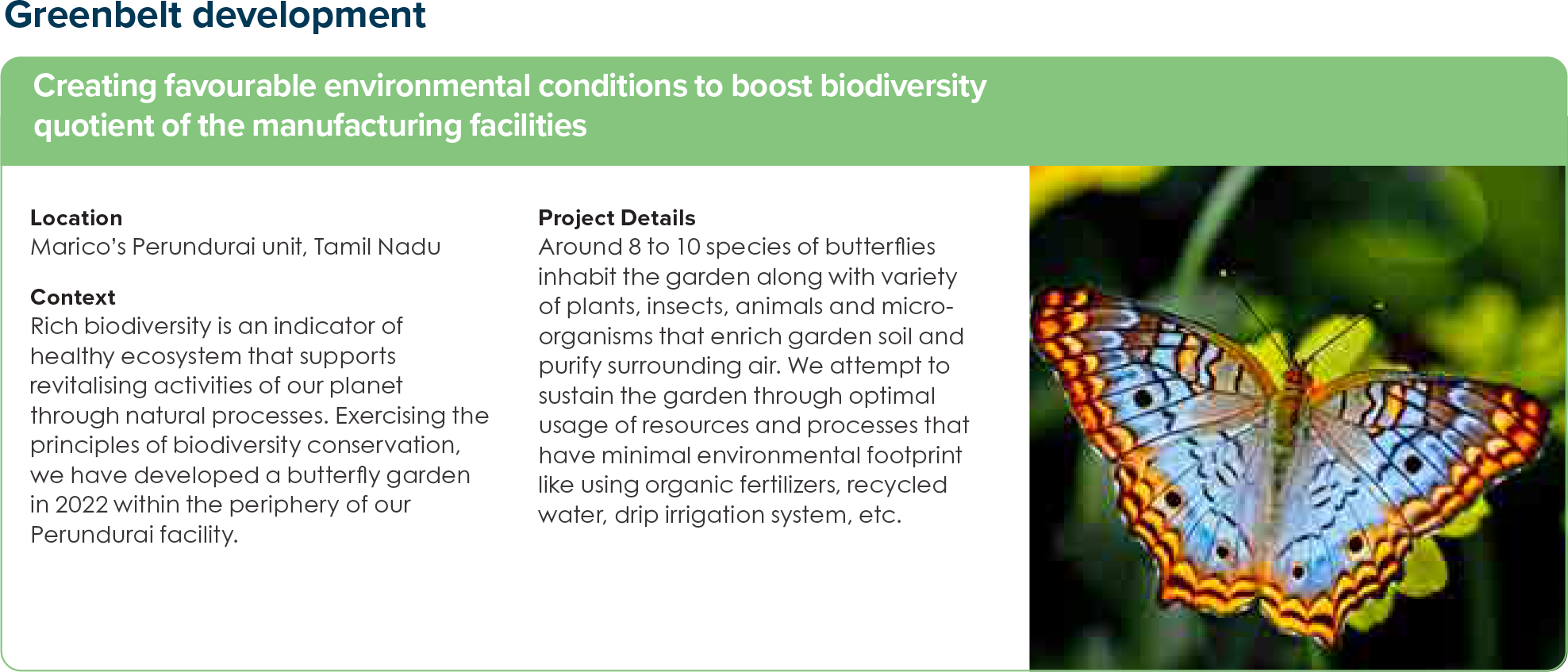

Marico’s Perundurai facility was certified as ‘carbon neutral’ by external assurance agency DNV GL. This is the third year in a row that this plant has received external certification on carbon neutrality.

The plant completely operates on renewable energy sources, and has been upgraded with smart energy installations that enhance the overall operational efficiency. Further, this plant has a Miyawaki forest spread over 3,000 sq. ft. within the premises. The goal behind this afforestation initiative is to develop a natural sink for carbon sequestration that offsets the minimal footprint from operations.

Marico Perundurai was awarded the prestigious CII-GreenCo Star Performer Award in FY22 for its extensive commitments and actions not just to mitigate environmental risks, but also to reimagine them as business opportunities, and making a greater difference.

Marico’s Perundurai facility

The Perundurai facility is Marico's first certified carbon neutral facility, and has also been awarded the prestigious CII GreenCo Platinum rating certification. In pursuit of creating a safe and sustainably built environment, this facility also received ‘Platinum’ level certification for achieving the Green Building Standards by CII - Indian Green Building Council (IGBC).

Energy Consumption

Marico has a central energy management cell, which works on a defined energy reduction strategy in conformance to the business goals and targets set for every year. Energy monitoring systems accurately capture the minutest reduction opportunities across the operational footprint.

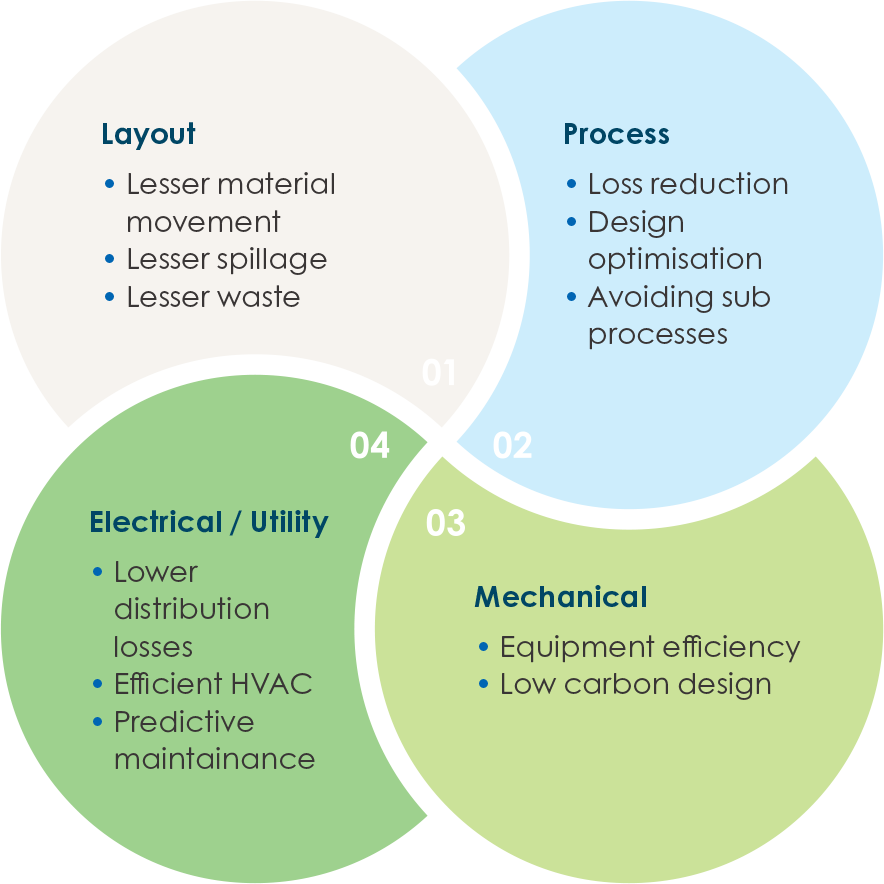

Through a set of strategically designed ideation sessions, energy management projects are executed throughout the year. Every change in process and equipment is checked for energy consumption against standards, while decision making. The energy reduction framework that is followed across Marico’s operational landscape is illustrated here.

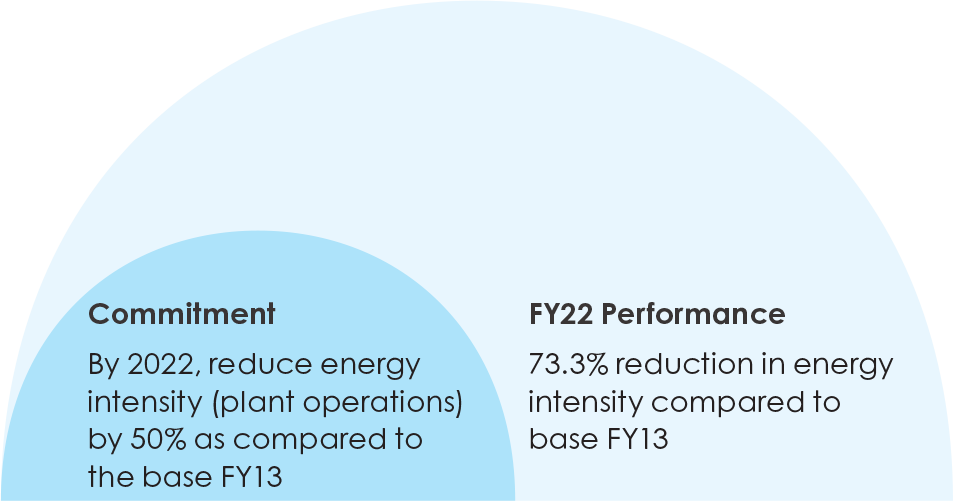

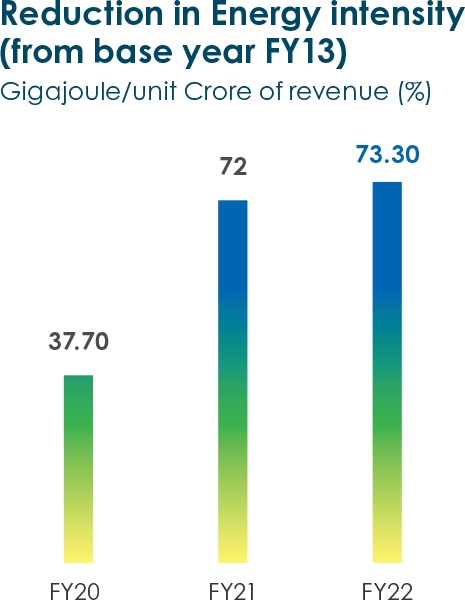

With respect to our 2022 commitment, we are happy to have surpassed the set target by achieving a reduction of 73.3% in energy intensity compared to FY13 base year. This has been possible because of our continuous focus on operations excellence achieved through optimisation of energy consumption, introduction of energy efficient systems, and exploring renewable energy options.

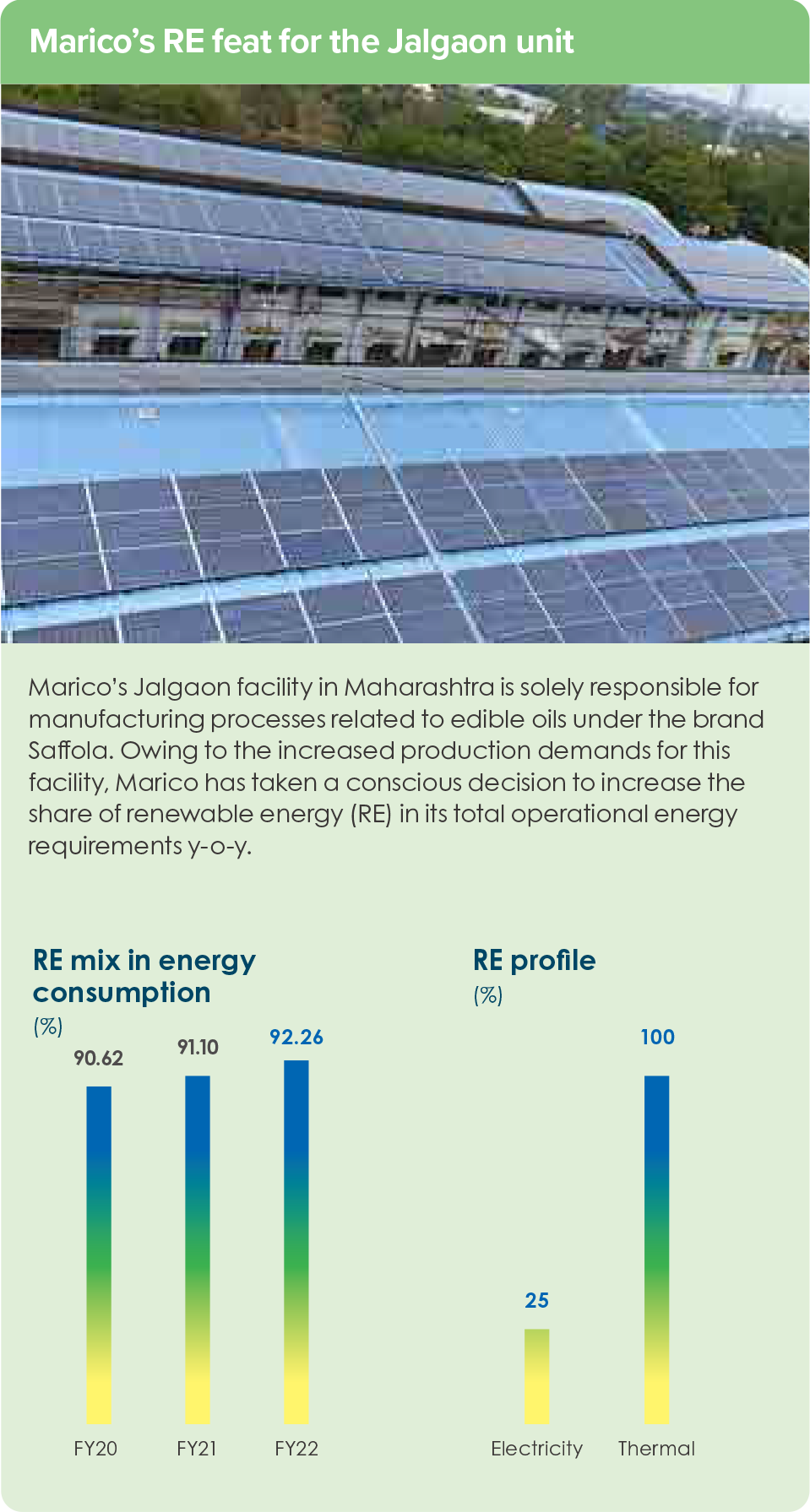

Transition to renewables

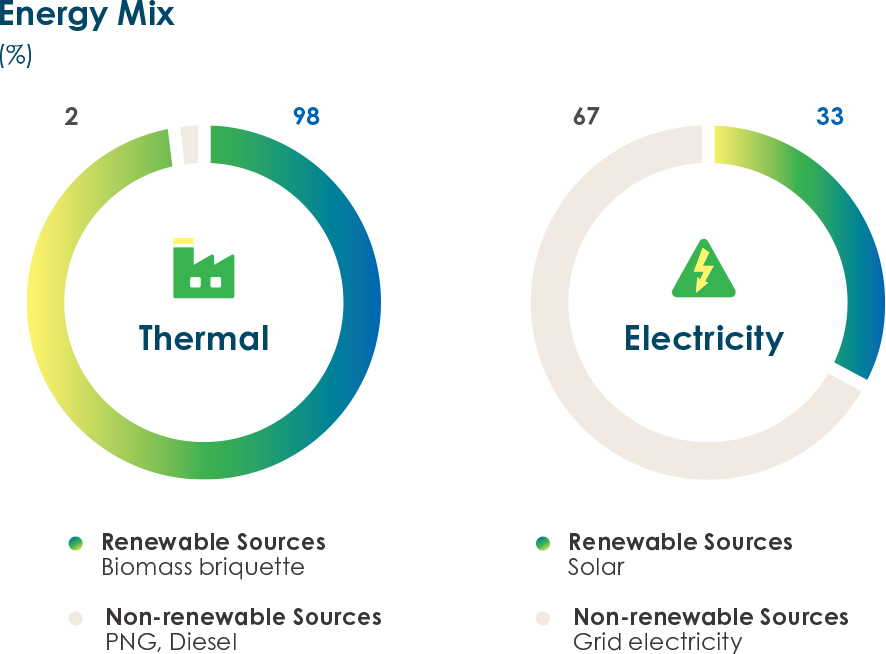

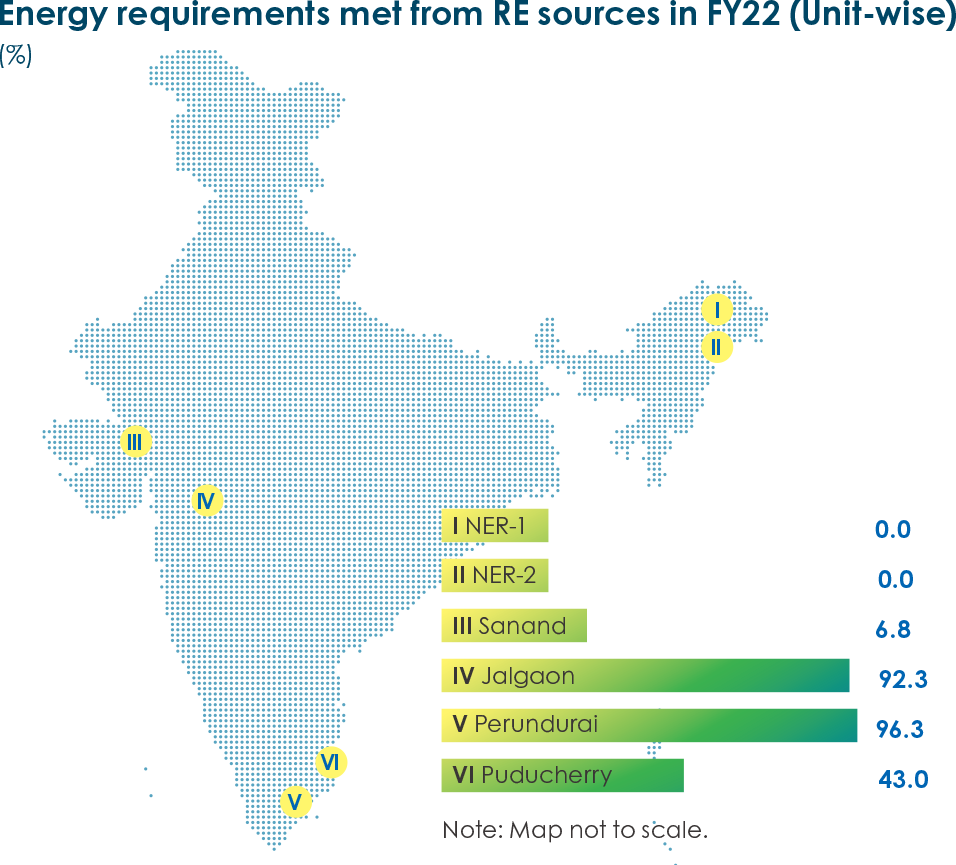

Our operational energy requirements can be categorised into thermal and electricity. The thermal energy requirement is majorly fulfilled by bio-based briquettes, making renewable energy (for heating purpose) contribute 98% of the total thermal energy used across operations. Remaining thermal energy is derived from Piped Natural Gas (PNG), and HighSpeed Diesel (HSD).

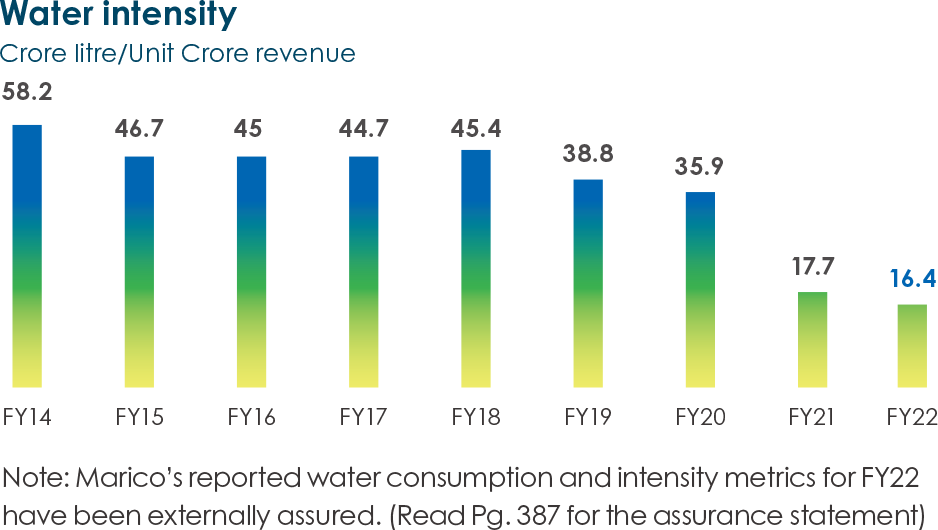

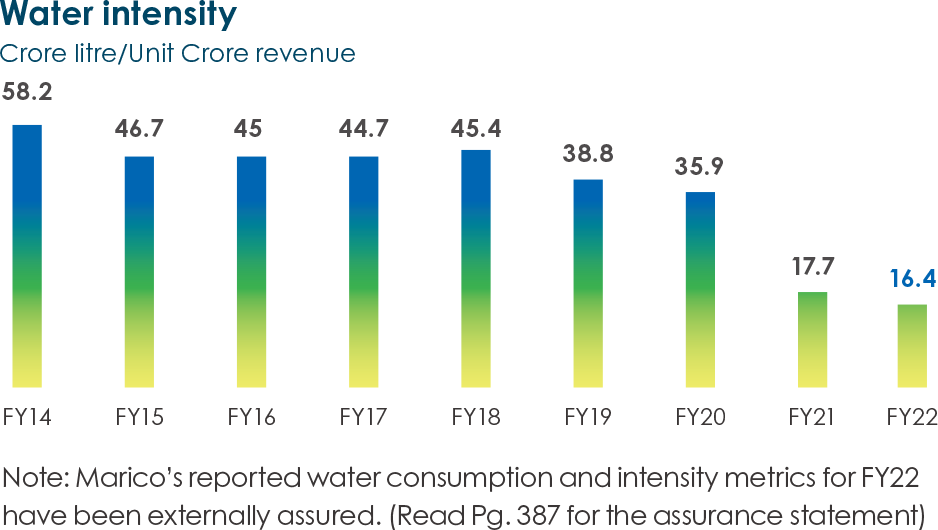

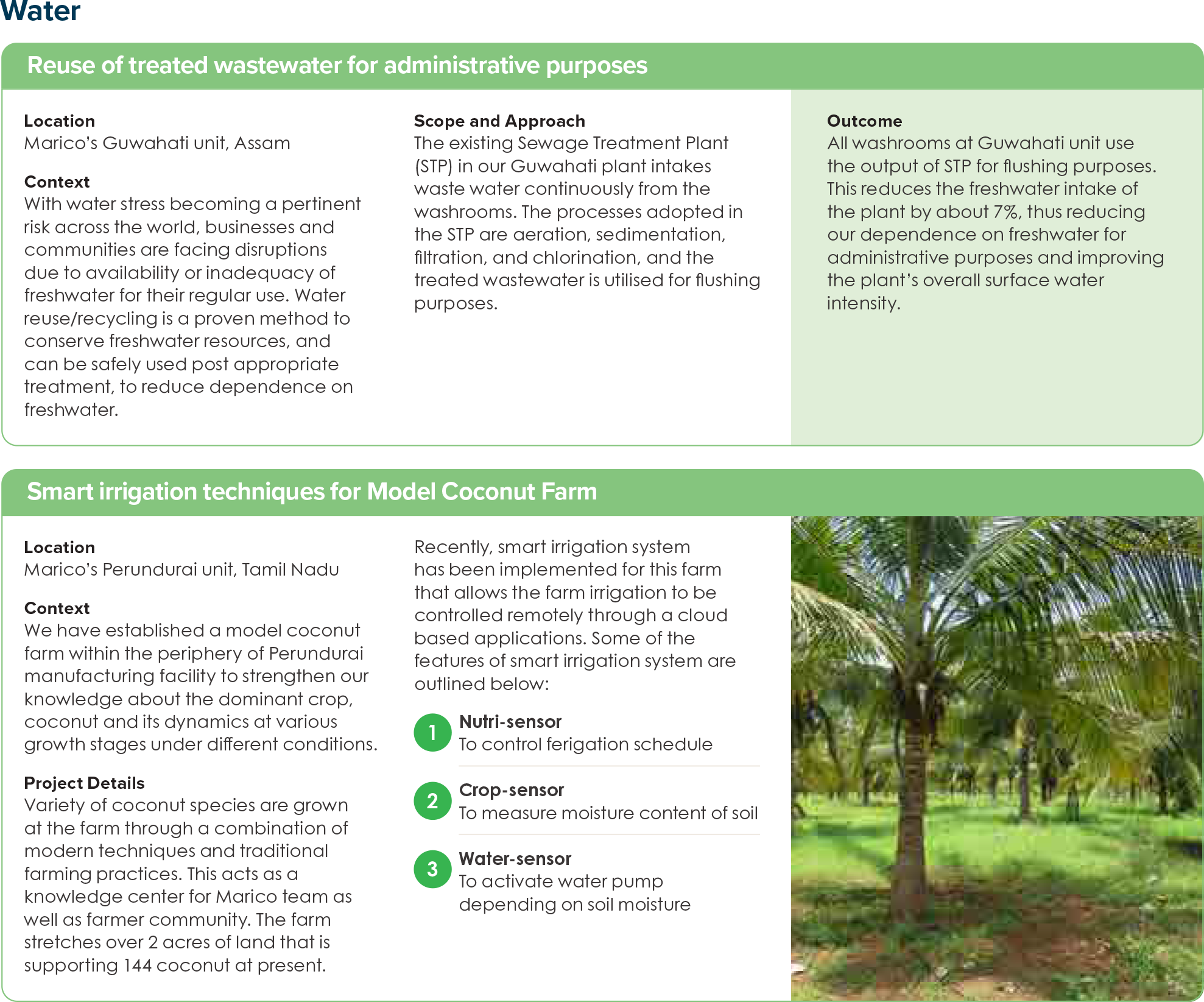

Offsetting water consumption

Over exploitation of water as a resource has given rise to severe water-stress-related challenges for communities and corporates. Businesses have the potential to limit the risk of water crisis by directing futuristic water management actions. As an early advocator of effective conservation and resource optimisation, we have been implementing state-of-theart solutions to minimise our dependency on surface water, ensuring judicious allocation of withdrawn water, and creating water storing capacity.

Envisaging the shortage of fresh water supply, we laid the foundation of our water stewardship strategy in FY18. The ‘Jalashay’ program is a product of this strategy, through which, we seek to offset our water consumption by creating water storage capacity for communities in water stress regions across the country. Dam desiltation, rejuvenation of water bodies, and construction of farm ponds, are some of the activities that we initiated under our water stewardship program over the last few years.

All the manufacturing units operate on the principles of zero liquid discharge (ZLD) model, and the entire volume of industrial effluents is recycled within the operational boundaries of our facilities, utilising the treated water for administrative and gardening purposes. Moreover, we attempt to utilise rainwater, harvested within our boundaries to reduce consumption of surface water sourced from outside.

Collective efforts across the organisation have contributed significantly towards the gradual reduction of our water intensity over the years. In FY22, water intensity was recorded to be 16.43, showing a 63% decrease from the base year FY14.

By virtue of our commitments towards water stewardship, we will continue to replenish more water for our communities, than we consume in our operations, every year.”

– Marico’s CSR Committee

FY22 Highlights

>3x

>3x

Water capacity created in FY22 as compared to total consumption in operations

~263 Crore litres

~263 Crore litres

Of water capacity created till date

246

246

Farm ponds constructed in Tamil Nadu in FY22

63% reduction

63% reduction

in water consumption intensity as compared to base year FY14

Managing Sustainability Footprint of Products

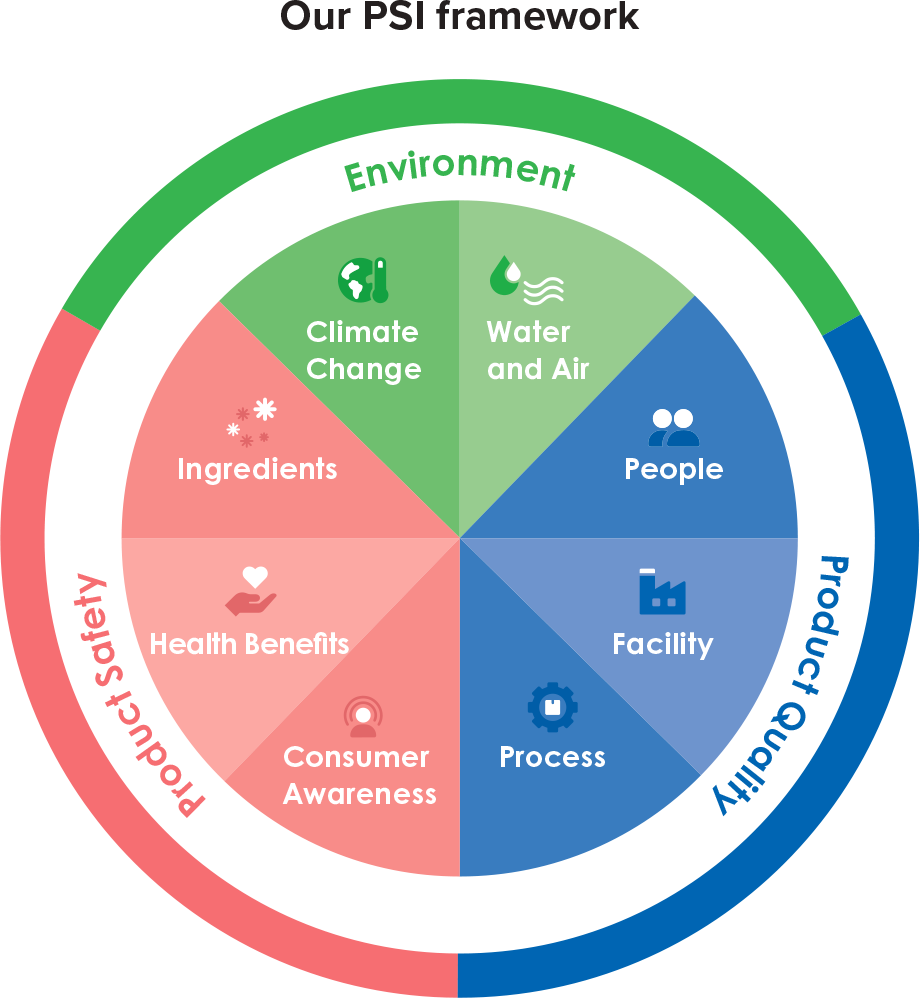

The future of sustainable business practices lies in the replicability potential of organisational goals across every aspect of the business. For Marico, this translates to the interlinkage that our organisational ESG agenda has, with sustainability footprint of products we manufacture. Developing a wellthought product sustainability index (PSI), aids in the transformation and innovation processes that facilitates successful and sustainable products.

It enables the organisation to integrate, implement, and measure sustainability objectives on a single platform, transforming it into a consumer-centric business that delights consumers and accelerates eco-conscious consumerism.

Developing a well-thought product sustainability index (PSI), aids in the transformation and innovation processes that facilitates successful and sustainable products.

Our Product Sustainability Index (PSI)

Marico’s PSI enables us to identify, manage and mitigate sustainability impacts in every stage of the product life cycle, from sourcing, to designing, manufacturing, transportation, distribution, and end-life disposal. Our approach is designed to help us foresee the potential environmental and social impacts of our products, thus helping us make refined choices to restrict negative externalities and extend benefits by institutionalising innovation within organisation and stakeholders.

In order to estimate sustainability of Marico’s product range, we use a self-developed index that considers quality, safety and environmental footprint aspects across life cycle. This index draws reference from over 150 international frameworks, research-based publications, and ecolabel certifications, and amalgamates the findings into a comprehensive index that not just measures the sustainability footprint of products, but also helps in benchmarking against some of the renowned world-class standards on product sustainability.

Marico’s robust PSI framework is scientifically developed to aid in the incorporation of sustainability measures early in the design phase, the validation of requirements, and the measurement of progress against corporate sustainability objectives, allowing for management of sustainability impacts throughout the products’ life cycles.

It provides a platform that allows for adoption, enables implementation, management, and measurement of sustainability goals, by providing a single source of product and process knowledge.

Developing a well-thought product sustainability index (PSI), aids in the transformation and innovation processes that facilitates successful and sustainable products.

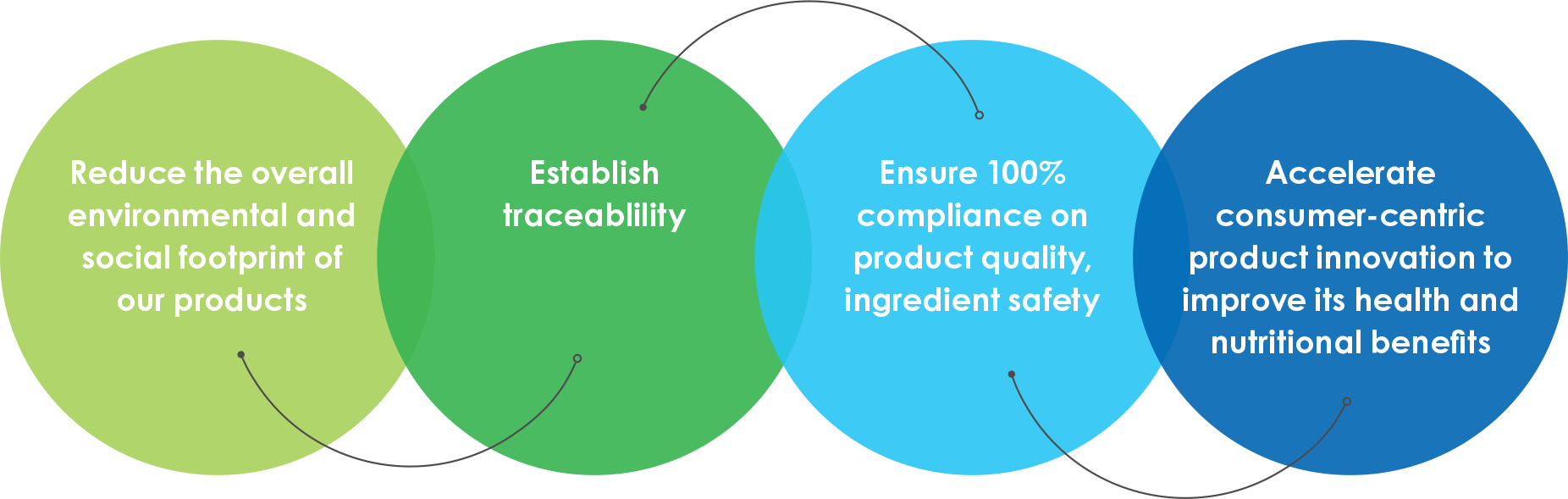

PSI aims to

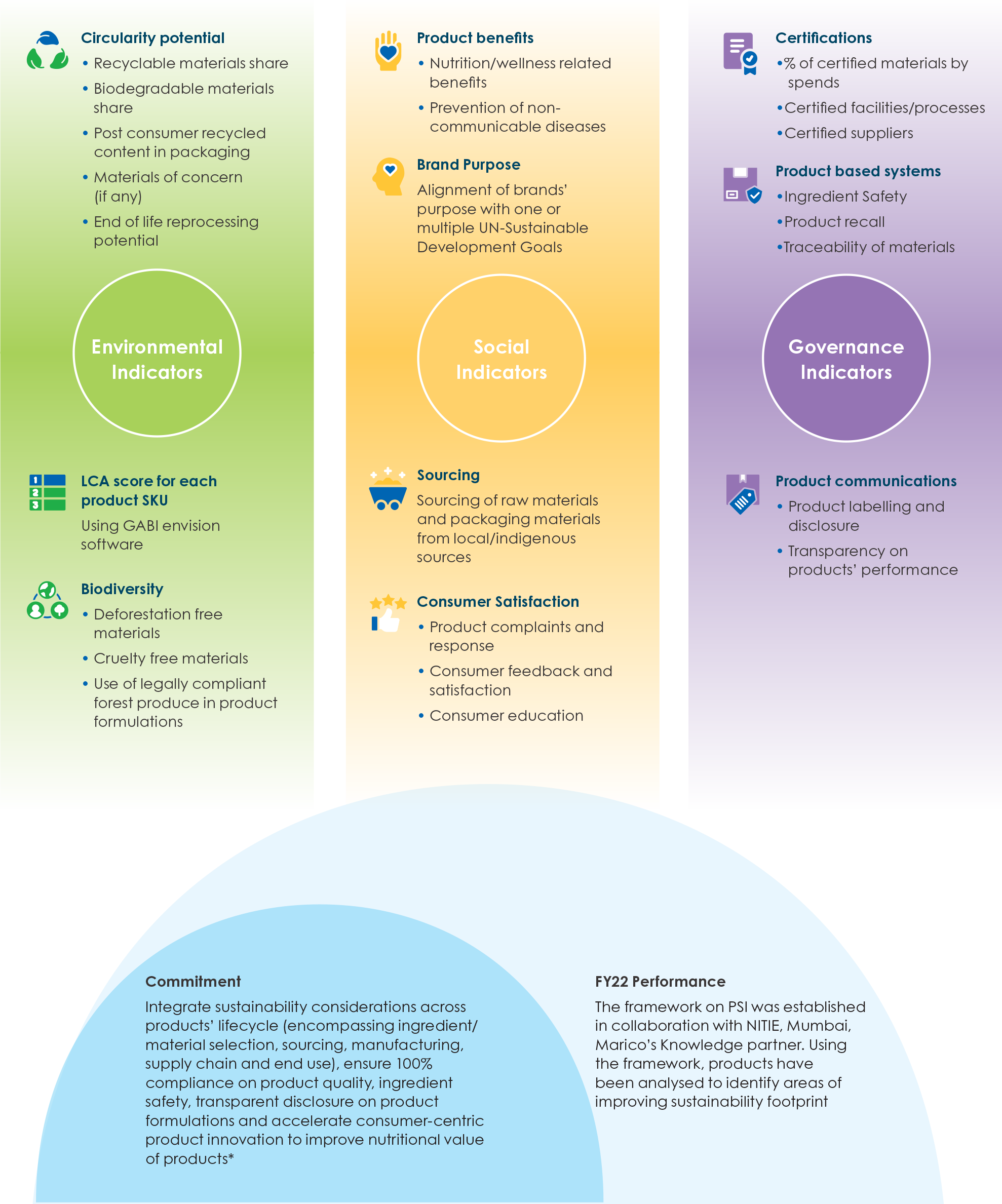

The framework includes a calculation methodology for quantifying the sustainability performance of specific product stock keeping units (SKUs) across a set of environmental, social, and governance indicators.

The PSI scale

The PSI scale is divided in three broad clusters/categories- environment, social, and governance, having pre-defined weightage of 50%, 30% and 20% respectively. Individual category is further divided into sub-categories where certain weightage is assigned to each sub-category. There are certain metrics under each sub-category that get scored on a scale of 0 to 4, depending on extent of adherence. Scores plotted against each metrics are compiled to determine the final score of each assessed SKU.

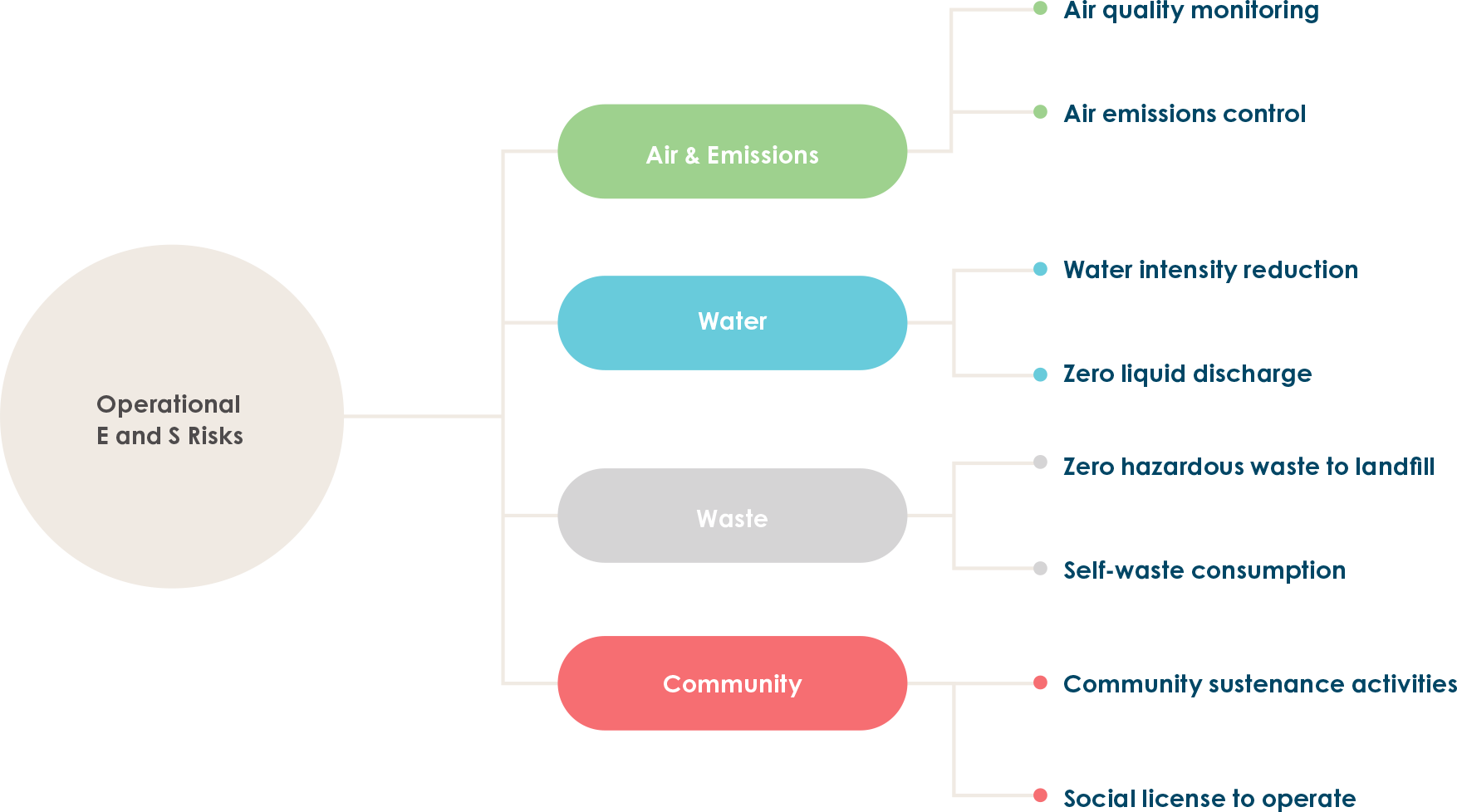

Mitigate Operational Risks

Our environmental and social risk management framework acts like a shield against emerging operational risks, making the organisation future resilient. It also helps in improving our performance and protecting the business against regulatory non-compliance.

In FY22, Marico did not register any environmental or social non-compliance

Environmental management in operations

Environmental and social risks existing within our operational boundaries are managed through efficient implementation, and timely review of innovative enterprises across following areas:

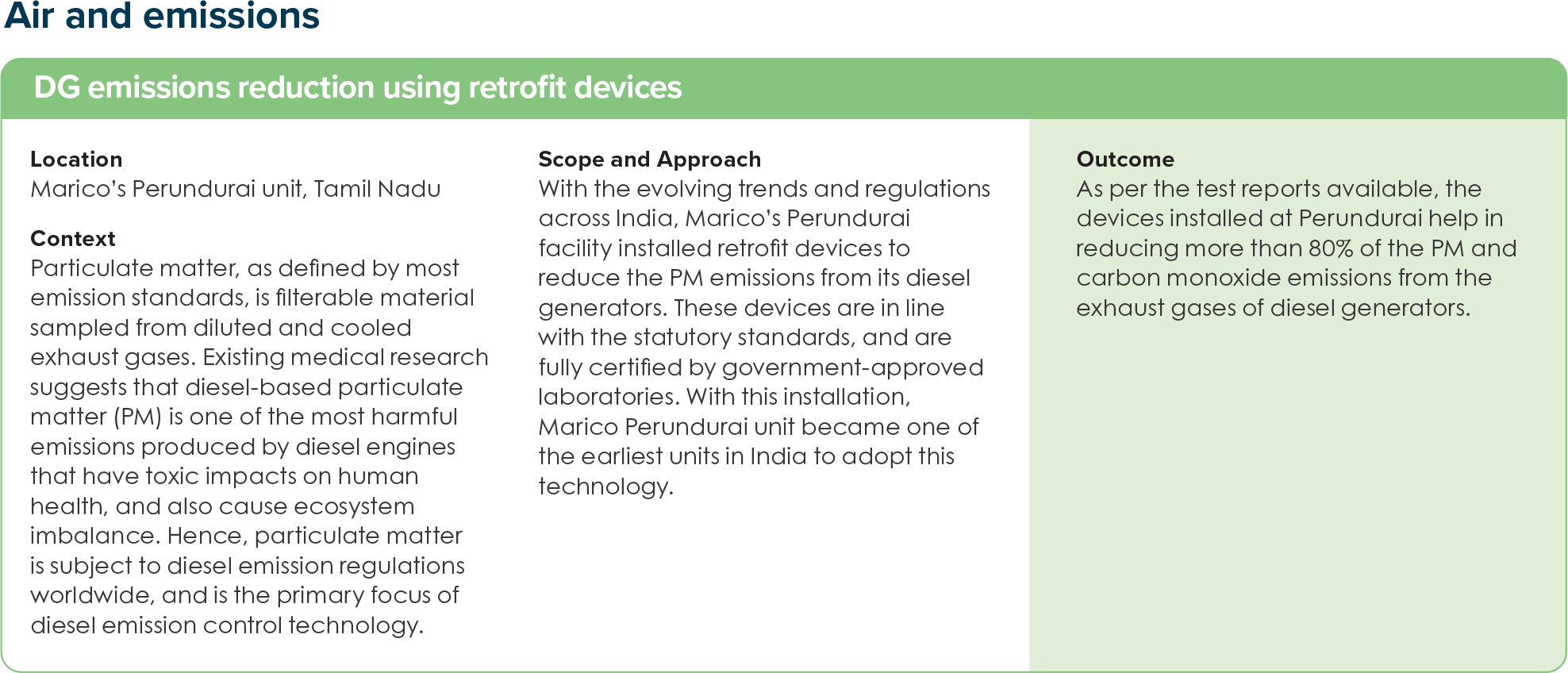

Some noteworthy projects conducted in FY22 towards minimising operational environmental risks include:

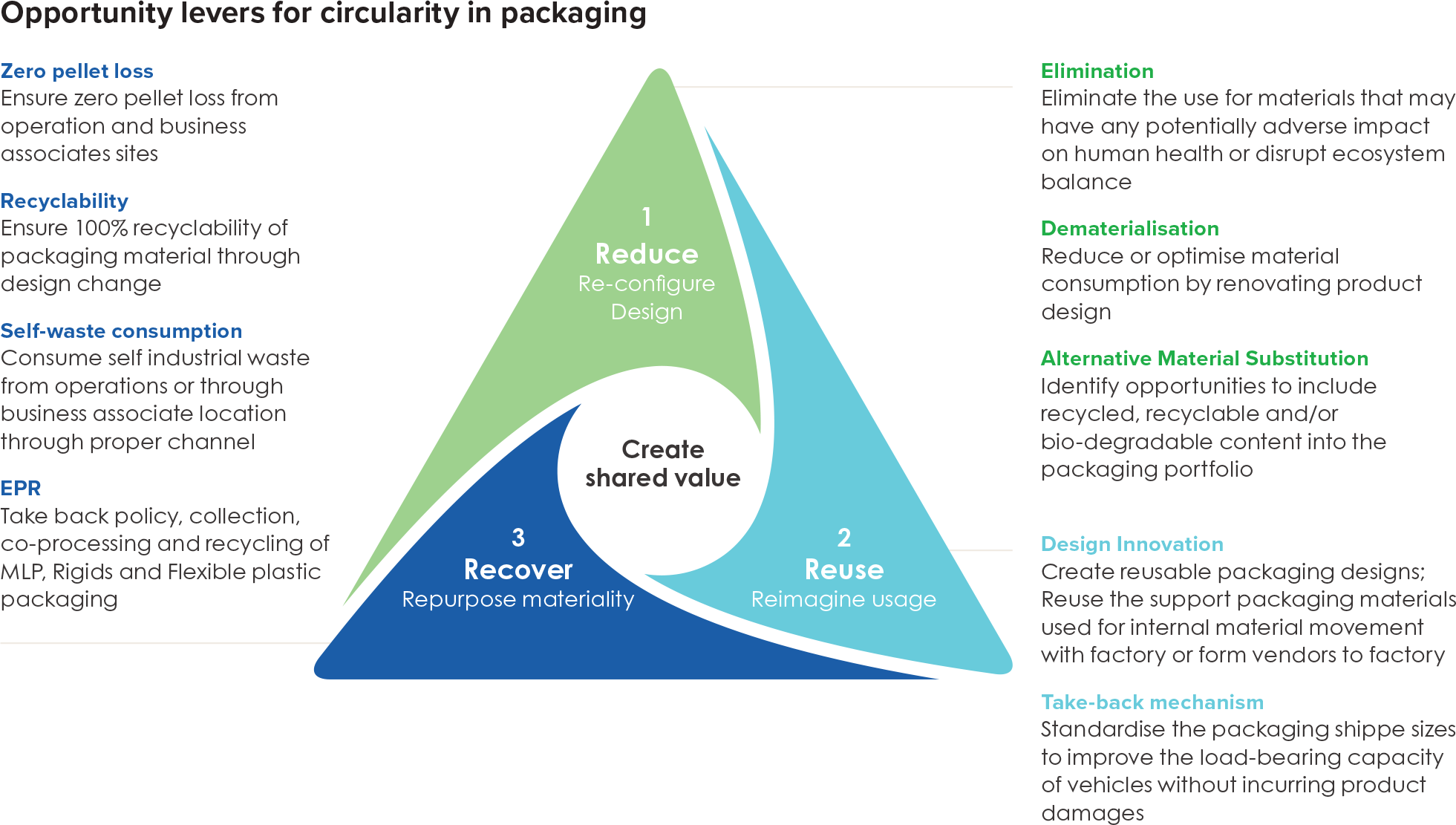

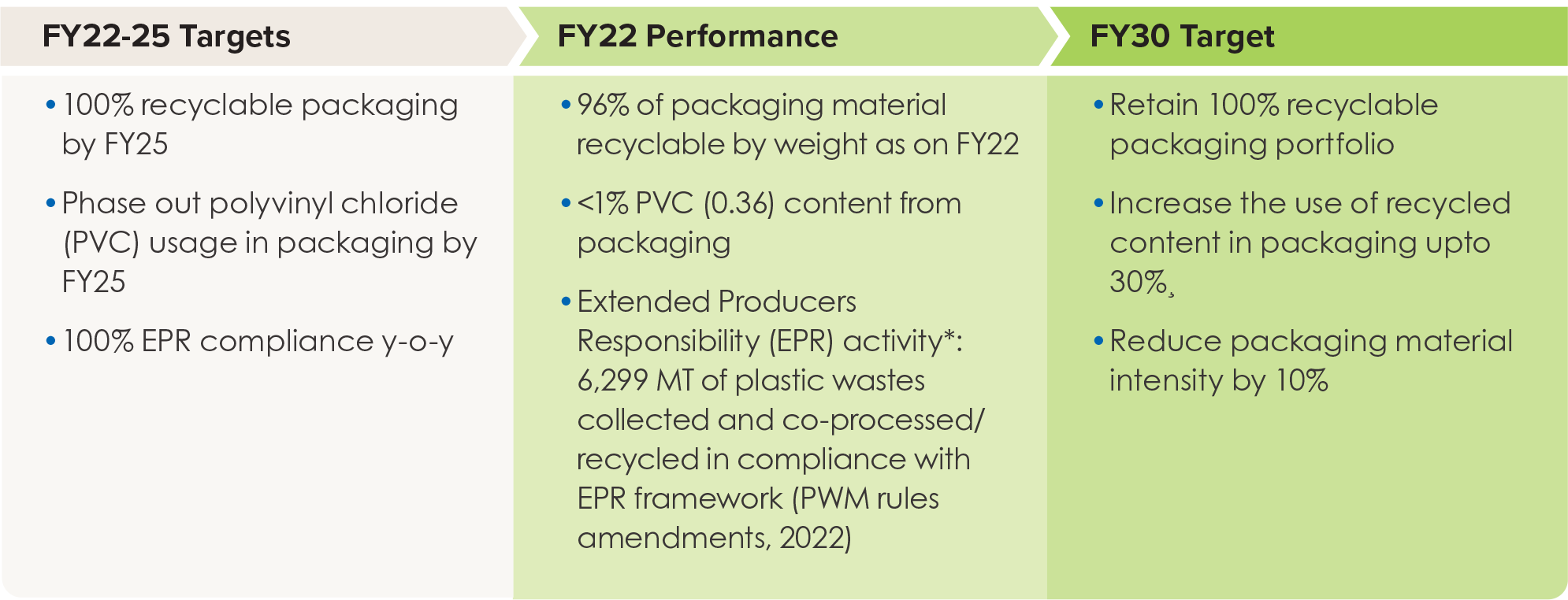

Integrate Circularity into Packaging

The demand for sustainable packaging solutions is gaining momentum with growing consciousness among consumers, policy makers, and industry leaders. At Marico, we reiterate our commitment towards a sustainable future by embedding circularity in our packaging portfolio, and extending our efforts beyond regulatory mandates.

Marico’s upcycle program is designed to integrate the principles and key performance metrics related to circularity within our overall packaging portfolio. A set of 9 opportunity levers have been established to accomplish the 2030 goals that have been set towards this material topic.

Combatting Plastic Pollution

Plastic being one the most light-weight protective material, is widely used for wrapping and encasing products. Having realised the environmental damage that plastic pollution is causing around the world, our research and development team is working on solutions to curtail wastage of plastic, and transition to recyclable, reusable, and compostable plastic packaging material. Options of including recycled plastic content in packaging are also being explored. We have already started reclaiming the entire process plastic waste by converting it into granules, and reusing it in packaging material production.

Product stewardship:

On the basis of the outcomes of the LCA studies undertaken for three of Marico’s flagship brands, Parachute Coconut Oil, Saffola Edibles and Saffola Oats, we identified several opportunities to reduce material savings and emission savings from the respective packaging portfolio by institutionalizing the principles of circular economy.

The key sustainable packaging interventions undertaken in FY22 include:

~12%

Reduction in Paper Consumption with HRCT Paper

~20% of PET

Recycled PET for smaller SKUs

50 to 36 microns

Downgauging of Labels

PVC to PET

Sleeves Transition

~4.2 tons p.a.

Holcobatch removal from Nihar Shanti Badam Amla

122 tons of LDPE

Polybag removal from 1 Ltr Saffola Oil

~11%

Reduction in weight of 25 FT

Ceka cartons

Introduced to replace BiB 200 gm of Soya Chunks

537 tCO2e

Overall reduction in emissions due to the aforementioned product stewardship initiatives undertaken in FY22

206 MT

Overall material savings due to product stewardship initiatives undertaken in FY22

Strategic alliances to scale up the sustainable plastic agenda for India Inc.

India Plastics Pact

To scale-up our circularity-based interventions within and beyond the sectoral boundaries, Marico decided to join hands with the India Plastics Pact, a transformational and collaborative platform created by WWF India and CII, anchored at the CII-ITC Centre of Excellence for Sustainable Development (CESD), with support from WRAP, a global NGO based in the UK. The Plastics Pact envisions ‘a world, where plastic is valued and does not pollute the environment.’

Marico is a founding member of the collaborative initiative that welcomes a multi-stakeholder approach to achieve collective target of transforming linear plastics system into a circular plastics economy, by enabling innovative ways to eliminate, reuse, or recycle the plastic packaging across the plastics value chain. The Pact has outlined a 2030 roadmap for achieving the quantifiable and aspirational targets, by accelerating business innovations through engagement, research, workshops, and co-creation activities. Besides driving circularity, the Pact aims to deliver significant GHG reductions through mitigations in fossil-derived plastics, greater use of recycled plastics, and increase in recycling.

The four targets that constitutes the Pact’s 2030 vision and roadmap are:

Define a list of unnecessary or problematic plastic packaging and items and take measures to address them through redesign and innovation

Define a list of unnecessary or problematic plastic packaging and items and take measures to address them through redesign and innovation

100% of plastic packaging to be reusable or recyclable

100% of plastic packaging to be reusable or recyclable

50% of plastic packaging to be effectively recycled

50% of plastic packaging to be effectively recycled

25% average recycled content across all plastic packaging

25% average recycled content across all plastic packaging

As a responsible member, we have set targets for using recyclable and reusable plastic, increasing the share of recycled content in packaging, and embedding social inclusion across the entire plastic waste ecosystem. We actively contribute to action groups, share on-field experiences, and report on annual progress pertaining to the roadmap.

Being a founding member of the India Plastics Pact, Marico has demonstrated great leadership by signing up to the India Plastics Pact.

Marico brings immense value to the initiative by sharing valuable insights and experiences as a part of the India Plastics Pact advisory committee, collaborative action groups, and technical projects, and hence, collectively contributing to solving India’s plastic waste challenge. The collaborative spirit demonstrated by Marico will help strengthen the plastic packaging ecosystem and synergise activities under the India Plastics Pact in transforming the linear plastics packaging economy into a circular one.”

Varun Aggarwal

Associate Director, Sustainable Business, WWF India

The Incubation Network

Each year, about 8 million tons of plastic waste enters our oceans, which is equivalent to 5 full trash bags, along every foot of coastline worldwide¹. The Incubation Network (TIN), an impact-driven initiative, aims to prevent plastic waste from flowing into the world’s oceans. By tackling waste mismanagement and implementing improved circular systems within the Asia Pacific region, the network intends to supports innovative solutions against plastic leakage by providing resources for capacity building, and foster a connected ecosystem of key stakeholders across the plastics value chain.

By safeguarding their wellbeing and implementing a strong gender equality mandate in our programs, the members of this network can ensure their work is fair and equitable across the sector. Marico joined TIN in FY22 to contribute actively towards the causes that advance circular economy within the Asia Pacific region.

Marico joined TIN in FY22 to contribute actively towards the causes that advance circular economy within the Asia Pacific region.

Extended Producer Responsibility

In alignment with the Plastic Waste Management (PWM) Rules, 2018 and the national guidelines on Extended Producer Responsibility (EPR) released in 2022, we had carried out collection, recycling, co-processing, and safe disposal of 6,299 MT* of post-consumer waste, including multilayer plastic (MLP), rigid and flexible plastic in FY22.

It was conducted across all the Indian states and union territories through authorised agencies. In order to ensure timely completion of our EPR activity, and confirm that handling, recycling, disposing, and documentation processes of our waste management agencies (WMAs), are in line with government norms, we appoint competent external agency to conduct independent third-party audit for selected WMAs and recyclers.

1,754 MT

MLP co-processed

2,283 MT

Rigid plastic recycled

2,262 MT

Flexible plastic recycled

Our journey with Marico for the last two-and-a-half years, has been of continuous growth through mutual trust. The collaboration has not only helped us facilitate the collection and scientific disposal of almost 800 MT of post-consumer plastic waste from Western and Southern parts of India, but has also helped in strengthening the infrastructure of the municipal bodies. We look forward to continuing this relationship, and contributing to a more sustainable world.”

Shailesh Shinde

Director, Social Lab Environmental Solutions Pvt. Ltd.

* In compliance with EPR framework published in 2022 by CPCB

Transform Value Chain Sustainability

Over the years, responsible sourcing practices have facilitated businesses to manage and mitigate a range of value chain risks, consumer preference, better compliance, and improved reputation.

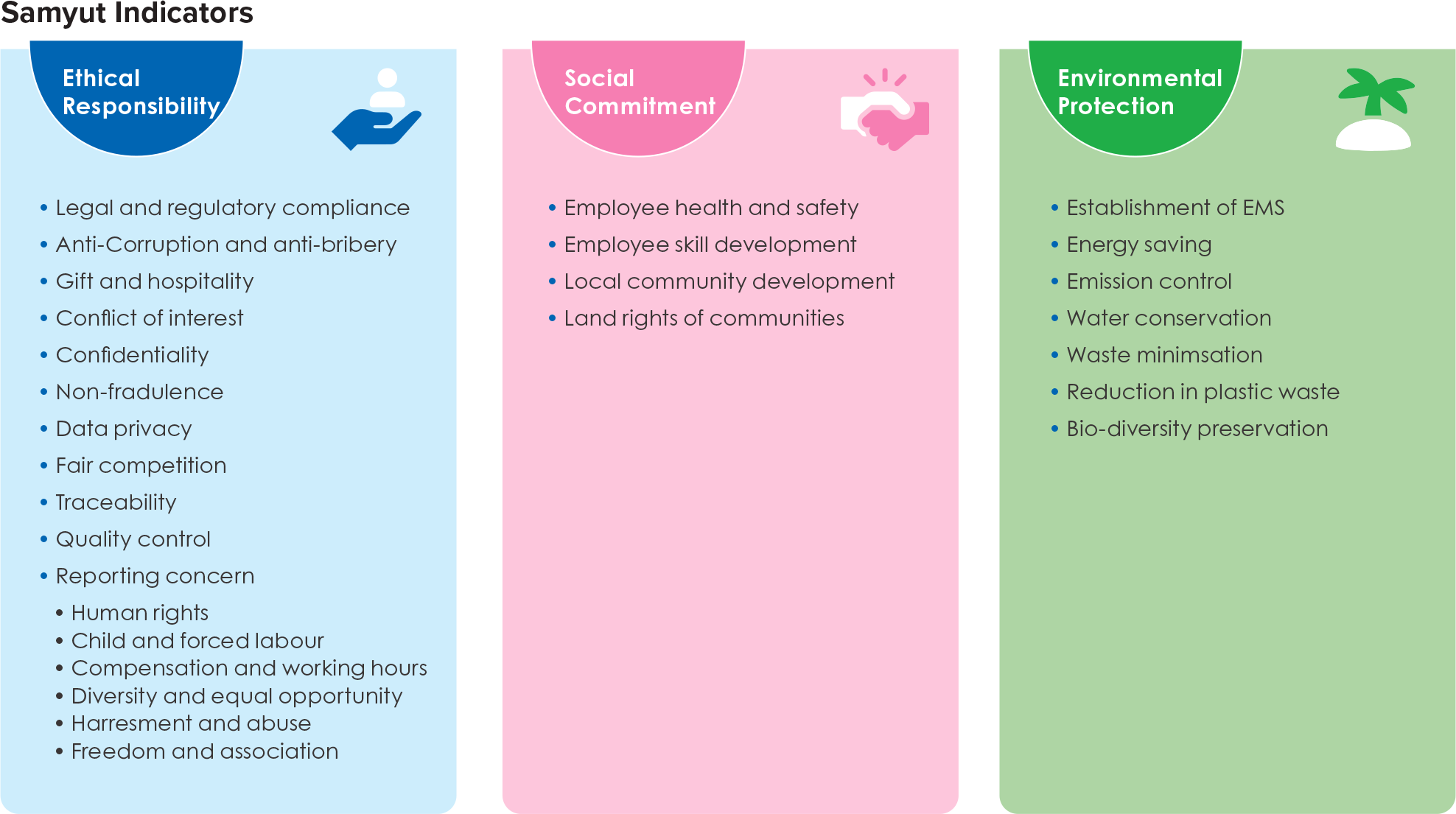

Through Samyut, Marico’s responsible sourcing program, we have extended sustainable practices throughout the value chain, with an objective to deliver sustainable and socially inclusive growth to all our partners.

Samyut- Responsible Sourcing Framework

Samyut, which, in Sanskrit, means coming together to achieve, endorses our intent of sourcing material and services through suppliers and business associates, who share our sustainability vision of upholding ethical standards, protecting environment, and empowering society through proper governance, while enhancing economy.

The Samyut framework was first institutionalised in 2018, with the overall business purpose of safeguarding stakeholder interests, and creating shared value.

Since then, the framework has undergone several modifications and improvements, keeping in mind the emerging economic, environmental, social, and ethical risks and opportunities that are relevant to our value chain. These updates encompass all relevant parameters covered under international standards like the UN-SDGs, Universal Declaration of Human Rights, and International Labour Organisation’s Declaration on Fundamental Principles and Rights at Work, among others.

Sustainability indicators under key thrust areas of the framework are enumerated below:

The Samyut framework is applicable for all our critical value chain partners, business associates and approved sub-contractors, including raw material and packaging material suppliers, logistics and transportation partners, warehouse and depot associates, third party manufacturers and service providers. Critical value chain partners are defined as using three criteria – Highest procurement share or volume share in the respective category, uniqueness of materials, products and/or services and dedicated association with Marico. We expect all our partners to refer and adhere to the terms indicated under Marico’s Samyut policy, and apply the outlined principles in their businesses.

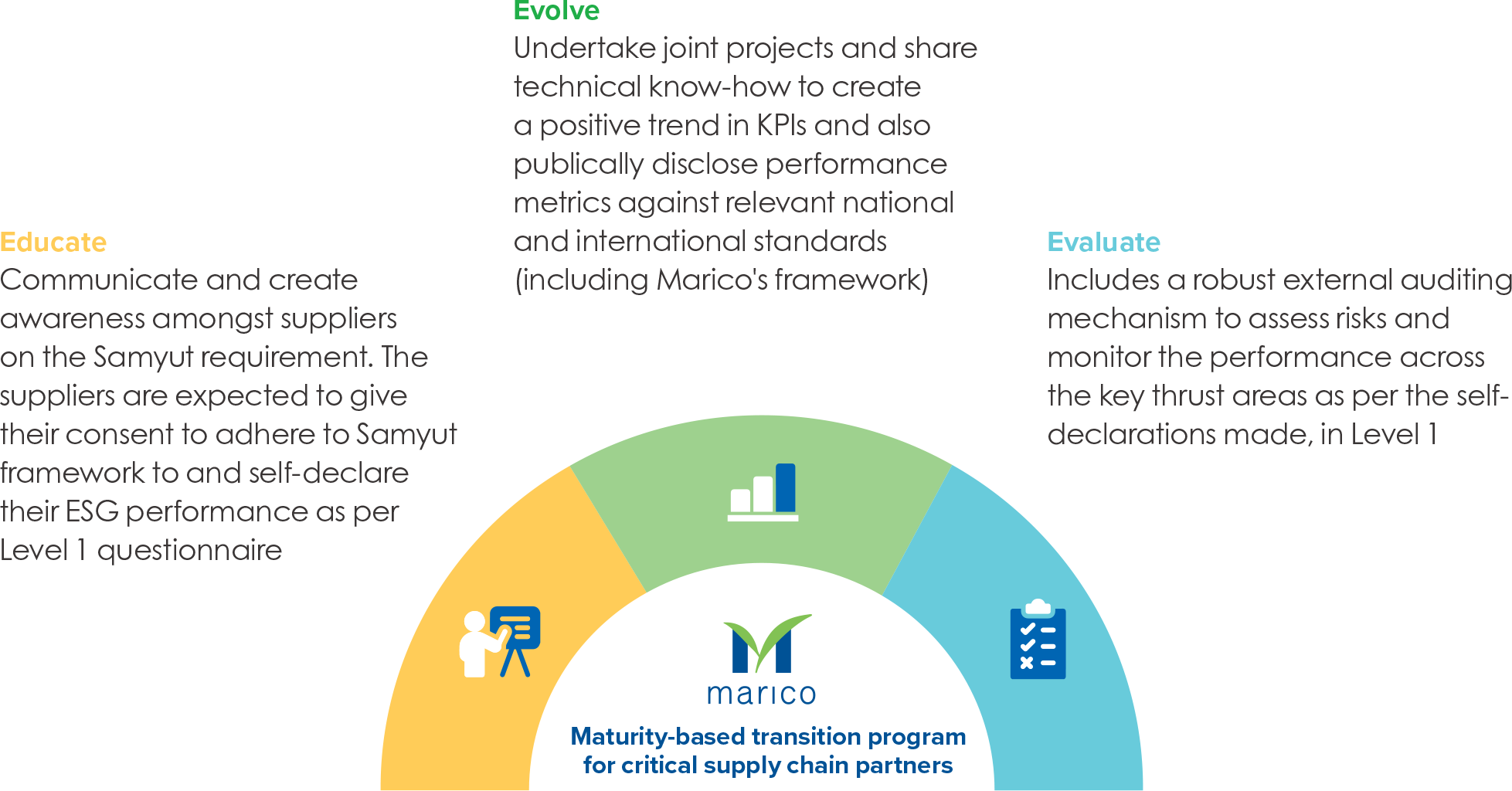

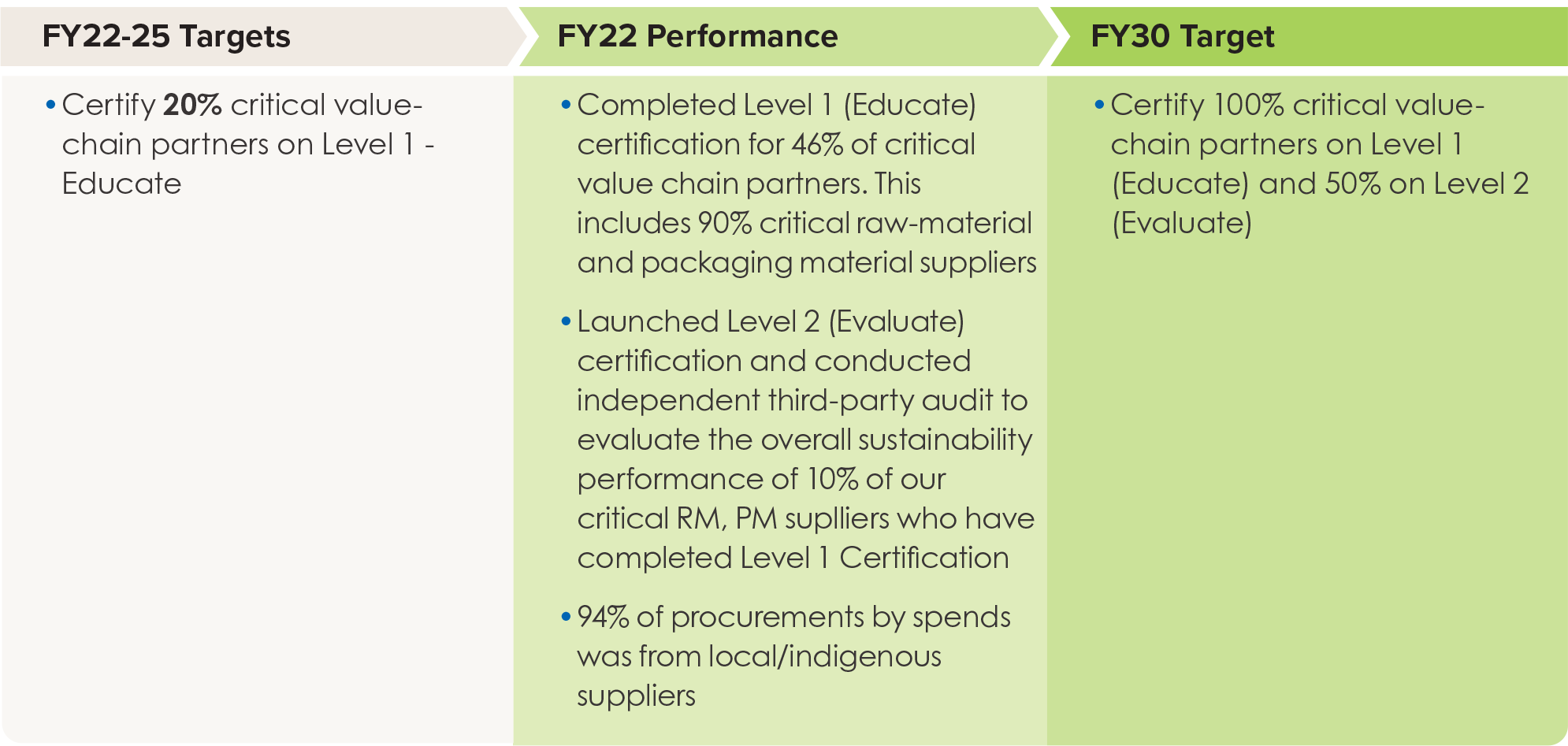

Under the purview of the Samyut framework, we have implemented a maturity-based transition program for critical supply chain partners, to foster joint sustainability efforts. The program is split into three levels: educate, evaluate and evolve.

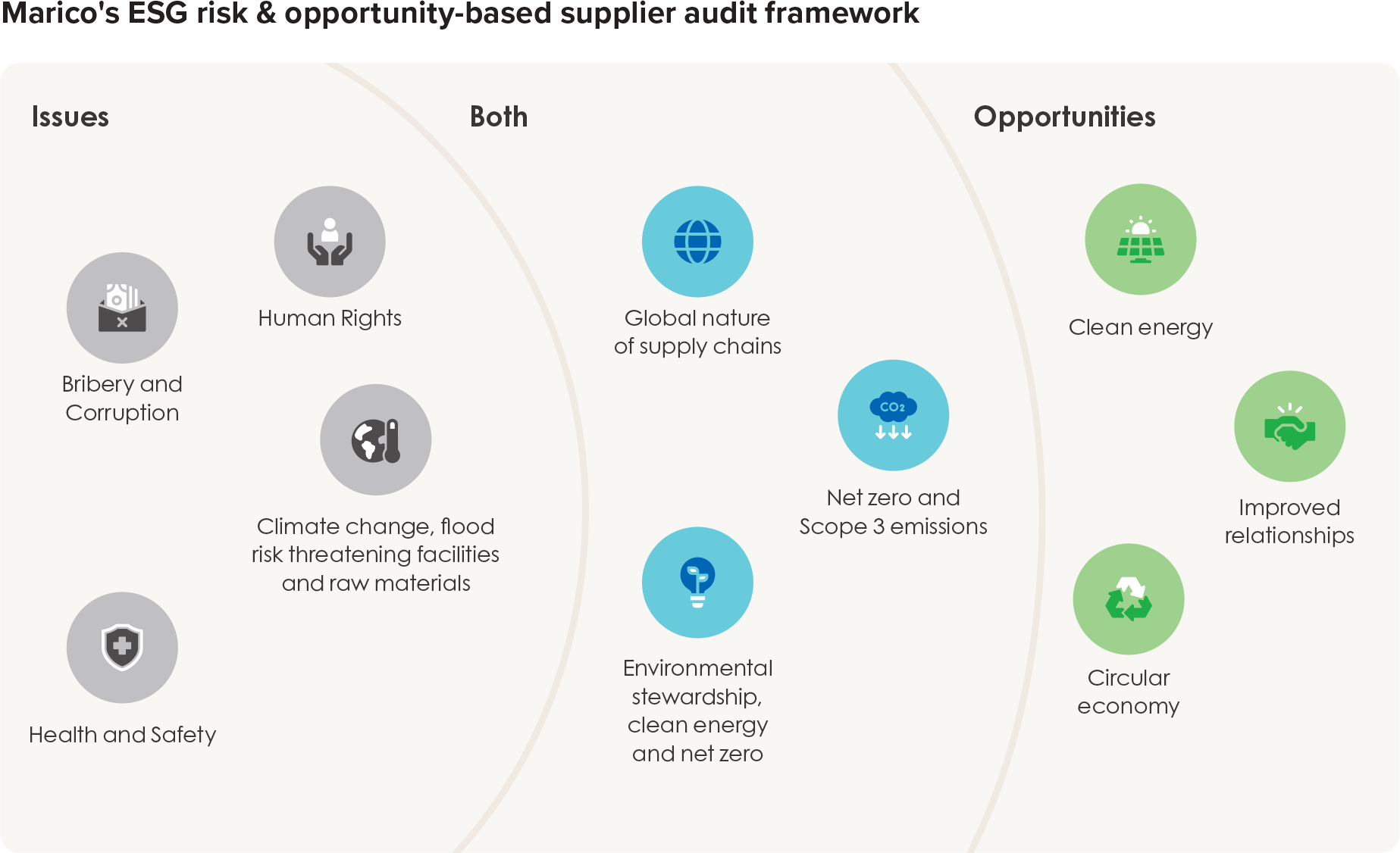

ESG Risk-Opportunity Evaluation framework for critical suppliers (Level 2 – Educate)

Marico’s value chain comprises a complex and interdependent set of products and services. As such, the relationship between these and ESG risk factors is intertwined throughout every level of the supply chain. To ensure transparency, accountability, traceability, natural resources optimisation, building safe and inclusive working environment, and incorporation of human rights and ethics at each strata of its value chain spectrum, Marico’s Level 2 principles have been crafted. It is the most critical step in Marico’s overall Samyut journey, with critical suppliers on-board. Here, we use a set of quantifiable key performance indicators across ethical, environmental, and social parameters, to evaluate the suppliers’ commitments, compliances, risks and potential opportunities, related to maximising sustainability impact in our business ecosystem.

The L2 assessments are typically undertaken by independent third-party auditors, who amalgamate the principles covered under Marico’s Samyut framework with their own extensive cross-sector sustainable supply chain experience. This combination allows them to scrutinise the voluntary claims made by critical suppliers in Level 1, and identify both, risks as well as opportunities that can have mutually impacting outcomes for Marico as well as the suppliers’ ecosystem.