Marico has Responsible Sourcing Policy and Supplier Code of Conduct applicable to our suppliers, business associates, and sub-contractors including raw material suppliers, packaging material suppliers, logistic and warehousing partners, third party manufacturers and service providers.

We continue to take forward Marico’s responsible sourcing programme, SAMYUT, to educate our value chain partners about our sustainability vision of upholding ethical, social, and environmental commitment through strong governance.

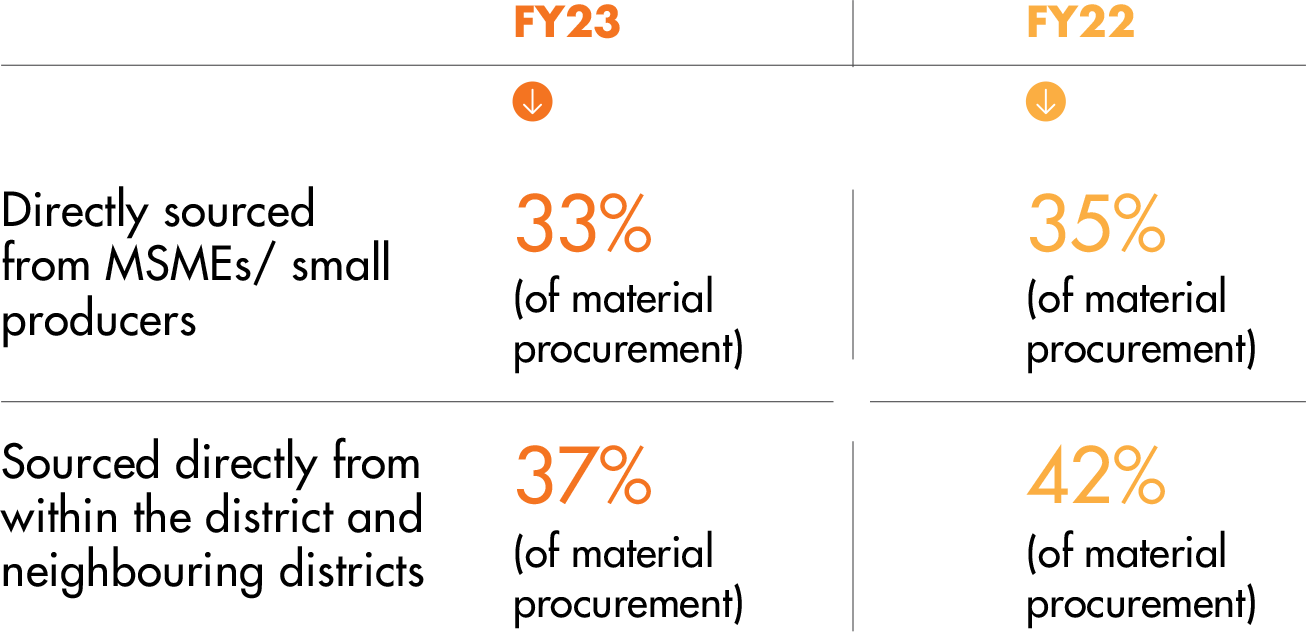

Our aim is to progressively increase our procurement spend on certified sustainable materials, local procurement, while improving diversity in our supplier base. A crossfunctional team has been entrusted to set the targets.

Marico launched its Responsible Sourcing programme to anticipate the emerging trends in value chain, identify and mitigate the risks and find opportunities for collaborative action with value chain partners.

The programme was introduced in a phased manner and intends to identify the risks across the value chain partners i.e., raw materials and packaging providers, depots and warehouses, and logistic partners.

We encourage our value chain partners to improve their environmental and social performance and also support their innovations to improve sustainability of our products across the entire life cycle.

In FY23, Marico has helped its business associates achieve Level 1 (L1) and Level 2 (L2) certifications. The following table summarises the achievement of Level 1 & 2 by the business associates. The audits are carried out annually.

Current % of Suppliers certified under SAMYUT Programme

Marico’s Code of Business Ethics (MCoBE) encompasses our philosophy, vision, policy, and actions towards integrating human rights and ethics in every stratum of the business. The following components of MCoBE ascertain that our partners understand and reciprocate our value towards protecting business ethics and human rights across the value chain.

Anti-bribery and corruption

Human Rights (Child Labour, Forced Labour, Wages, Working conditions)

Diversity & Inclusion

Safety, Health, and Wellness

Prevention of Sexual Harassment

Sheltering numerous sustainable implications, local/indigenous procurement has reserved our preference. It reinforces flexibility, transparency, and control over supply chain, thereby establishing stability in operations.

As of FY23, 94% of our procurement by spends were from within I ndia. 45% of the material by procurement spend was sourced from suppl iers that have received L1 certification under SAMYUT.

The supplier selection process is applicable for the procurement of commodities and non-commodities by the organisation. The policy guidelines elucidate the following stages in the standard vendor evaluation process:

New vendors are identified from diverse backgrounds and are on-boarded after rigorous screening assessment.

Capacity Development programmes are organised intermittently to resolve quality issues, drive innovation, enhance performance and assure time-bound supply. This strengthens our long-term relationship with our value chain partners and helps us derive competitive advantage.

The Company ensures that statutory dues as payable by value chain partners to their employees through a process of internal controls and periodic audits. Marico emphasises labour law compliance to its value chain partners through the Supplier Code of Conduct.

The procurement and central quality assurance team at Marico collectively drives the Supplier Quality Excellence (SQE) programme, which aims at capacitating our Packaging Material (PM) suppliers to accelerate performance and deliver excellence. During FY23, 22 packaging material suppliers attended the SQE programme. It also witnessed keynote speeches from our associate experts.

Based on and in line with recognised schemes of Global Food Saf ety Initiatives (GFSI), Marico’s ‘Supplier Quality Excellence’ programme aims at enabling value-chain partners to ensure that supplied products are safe, legally compliant and conforms to agreed quality specification.

As-is study & benchmarking with Industry best practices

Periodic Marico audits & developing Supplier Self- Audit capabilities

Conducting training programs for vendors & organizing external speaker seminars to enhance Supplier capability

CAPA documents on quality issues & knowledge transfer to other relevant vendors to prevent repeated issues

As a participant in quality excellence program, we got opportunity to learn about quality approach to reduce customer complaint by brainstorming via various quality tools. As a supplier this program helps us to understand design and progress reviews statically process control. By this program, we learnt how to be consistent meeting the requirements of our customers in product safety and quality. – PAHARPUR.

The SQE event was a good and enriching experience for Amcor team. It is a great platform for packaging converters to come together and brainstorm on quality issues pertaining to the packaging industry as a whole. The case studies discussed by a few suppliers were a good learning for us and will be helpful for us to mitigate similar issues that we might face in our supplies to Marico and other customers as well. - AMCOR

The SQE Meet 2022 was very fruitful and well organised. The case studies & discussions helped us benchmark our Quality Systems & Conversion Process with the Current Industry Practices. It also made us abreast of the trends in other segments like flexible, rigids etc. I take this opportunity to thank Marico for organising the event and earnestly looking forward to further events. - MAKERS POLYFILMS PRIVATE LIMITED.

Hackett Portal was launched in FY23 to improve efficiency, while maintaining compliance. It has helped in effective monitoring of quality issues and enabling data analysis on the overall complaints received. The portal is made available to all stakeholders including external vendors to facilitate transparency and quick resolution of any issue.

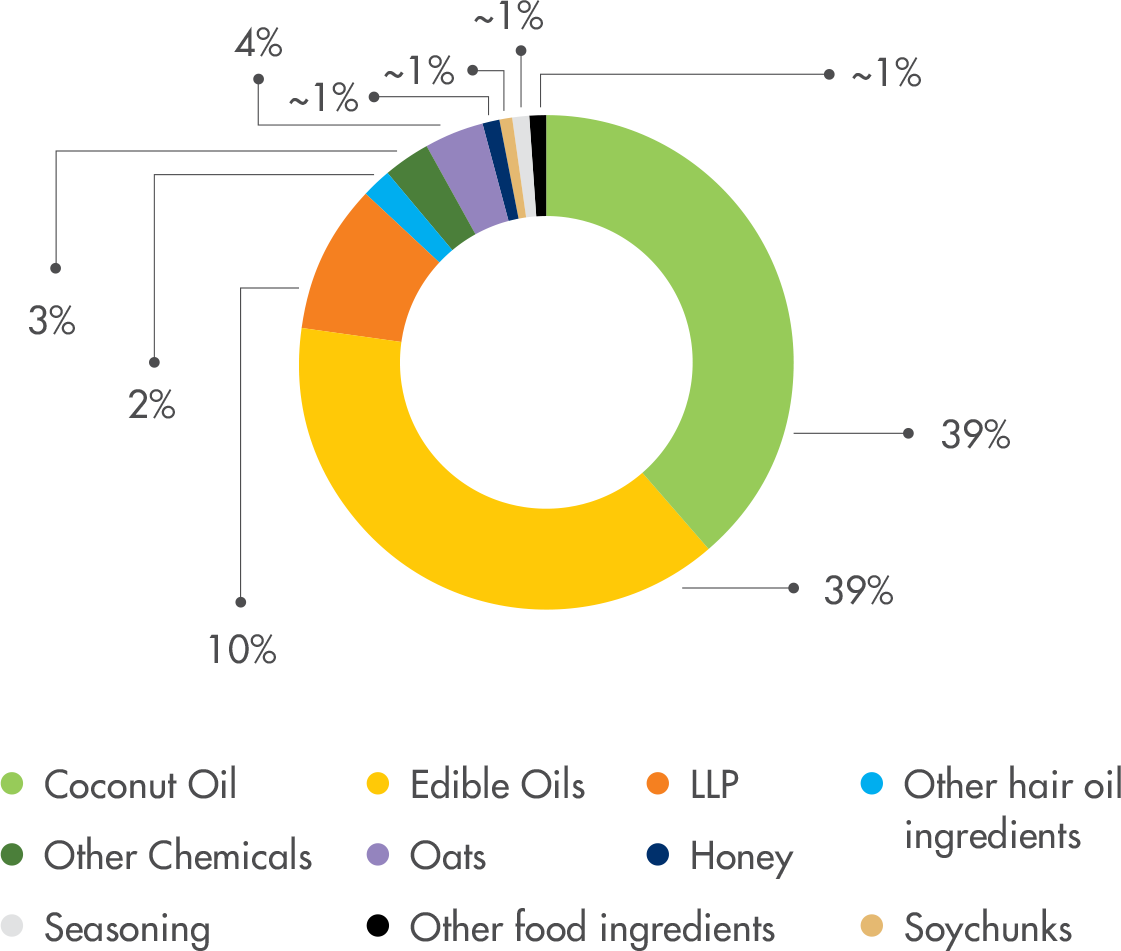

A majority of the procurement expenditure in raw material is attributed to the procurement of coconut and edible oils.

Upstream supply chain, especially of raw and packaging materials, prompt production and distribution patterns tacitly influence consumption behaviour. We prioritise supplier relationship management that operates with the philosophy of creating synergistic business goals and inspire our partners to deliver excellence and efficiency. Some of the important facets of supply chain that we pay special attention to, while maintaining supplier relations are described here:

Convertors share the responsibility of transforming our products into packaged finished goods, that are ready f or dispatch. We assist our partners by:

Safety, health and environment (SHE) initiatives.

Technology upgradation

Quality management

Operational excellence

Process modification

Capability building

Our downstream value chain partners, depots and warehouses, facilitate smooth delivery of our products in different regions. We facilitate their capability elevation journey by means of several engagement programmes.

We have adopted an integrated approach on identifying potential risks and hazards, prevention of hazards and protection of personnel against occupational risks. Every manufacturing partner and depot operator is expected to follow health and safety guidelines covered under SAMYUT Policy and qualify a set of critical SHE criteria to continue their associations with Marico.

SHE trainings are conducted in a Trainer-to-Trainer Model for the warehouse managers and workers. Monthly reviews and external agencies are appointed for due diligence on their incident preparedness and proactiveness to mitigate future risks. In FY23, Safety Health and Environment audit was conducted by an authorised third party.

Approximately 500 manhours were spent in FY23 towards safety trainings to depot personnel and contractual workers on themes such as fire safety, electrical safety, loading/unloading techniques, along with storage/ handling, crisis management, Leakage & Damage, Food Safety, DQR & QMS (Quality Management System) Goods in Transit and waste management.

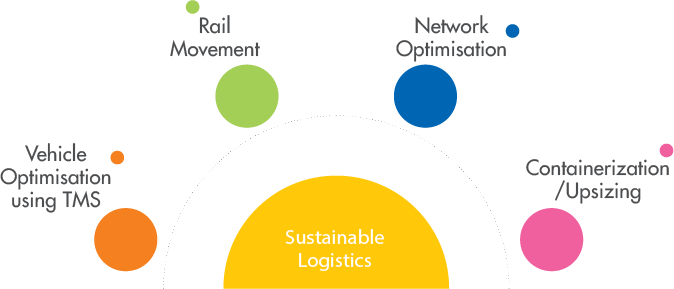

Our logistic and transportation partners are crucial for planning, execution and monitoring of product movement, while bypassing geographical limitations.

Our initiatives with logistics partners are designed to build an agile and sustainable distribution network with a wider market coverage at competitive costs.

We are driving cost-effective and sustainable distribution network by monitoring levers such as distance travelled per trip, load-ability per truck and opting greener modes of transportation.

Network optimisation has helped in reducing many unnecessary trips and proposed better routes has led to less fuel consumption. We have identified lanes where direct dispatches from the manufacturing plants can be done to remove secondary movement.

We closely monitor the vehicle utilisation for all our movements to ensure that all trucks are at least 95% utilised. This, in turn, helps reduce the number of trips and cut down our carbon emission. Also, we are extensively using Transportation Management System to optimise our vehicle requirement and ensuring that right vehicle type is used for any movement. Additionally, there are few lanes where we can use a more energy-efficient way of transportation i.e., Railways. With the volume growth, we will be able to open more lanes for Railways. Going forward, we are exploring ways of using technology to improve efficiency of Marico’s Supply Chain.

We are also identifying avenues to promote the usage of electrical vehicles and clean fuels in our logistics operations.

Marico engages with the value chain partners on identified material needs including supplier code of conduct, safety and operational risk management, quality, environmental responsibilities and payment modalities.

Our engagement mechanism consists of periodic interactions (physical, over telephone, via emails), annual meet and training programmes. Our main engagement objectives are to share mutual needs & expectations, capability building & growth plans and best practices.

| 01 |

Marico code of business ethics covers business ethics, legal compliance, prohibition of corruption and Bribery, labor, human rights, health and safety, environment protection. |

The training module was extended to all critical business associates related to raw materials and packaging materials. Vendors representing 69% of procurement by spend participated in the training session. |

| 01 |

|

More than 80 vendors representing 25% of procurement by spend attended the session. |

| 26 |

Quality assurance |

More than 17% of vendors by procurement spend have participated in quality training related to raw materials (Copra). |

| 04 |

Safety, Health & Environment |

|

| 03 |

Quality assurance |

80% of vendors providing primary packaging material to Marico participated in the training. |

The above image gives a glimpse into one of Marico’s annual events, where our business partners interact with the Leadership Team, in person. A plethora of topics, pertaining to business goals, emerging trends etc. are discussed

Marico strongly believes in helping its business associates in their sustainability journey. With this intent, we have put in place a robust system of internal reviews and audits.

Marico has an oversight of its business. It also engages an independent Third-party to carry out annual audits. Through these audits, Marico not only helps these associates comply with the laws of the land, but also help them improve the working conditions of their people, introduce measures to develop efficiency in transportation that provides safety for goods, drivers, and all concerned stakeholders.